ABSTRACT:

The

paper

presents design of hybrid active power filter (HAPF) in a three-phase

three-wire power system. Design is implemented with instantaneous reactive power

theory for control of HAPF in order to mitigate harmonics generated by both

non-linear and unbalanced load at the point of common coupling (peC). The p-q

Theory enables the source current to be decomposed in αβ0 frame to obtain

compensation current for each phase. The hysteresis band current controller is

used to generate gating pulses for voltage source inverter (VSI). Over all

harmonic reduction is achieved via the proposed control of HAPF and the THD levels

are per the IEEE-519 standard. Investigation of proposed scheme is validated by

extensive simulations using MATLAB / Simulink Sim-Power System tool box.

KEYWORDS:

1.

Harmonics

2.

Passive

Filter

3.

Active Filter

4.

Hybrid Filter

5.

Power Quality

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

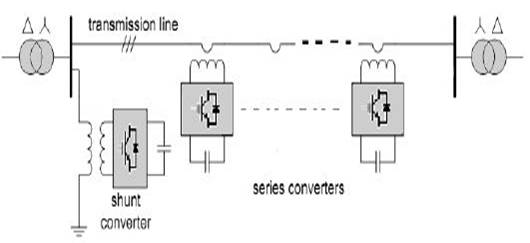

Fig. 1: Basic Diagram of SAF

EXPECTED SIMULATION RESULTS:

Fig. 2: Source Current THD (29.9%)

without Filter

Fig. 3: Source Current THD (10. I

5%) using Passive Filter

Fig.

4: Source Current THD (4.47%) using Active Filter

Fig.

5: Source Current THD (2.02%) using HAPF

Fig.

6: Compensating Current for Phase a,b and c

Fig.

7: Load Current THD (10.39%) in HAPF

CONCLUSION

This

paper highlights the efficacy of HAPF for improving the power quality by

eliminating harmonics from power system. The HAPF with a constant power compensation

control strategy and hysteresis-band current controller is proposed. A thorough

simulation based investigation validates the competency of HAPF among all

filters for harmonic mitigation in power system due to current quality problem.

The performance examined has demonstrated the efficiency by reducing the source

current THD for non-linear load. The THD is well below the specified limit

ofIEEE-519 standard.

REFERENCES

[1]

A. Baitha and N. Gupta, " A comparative analysis of passive filters for

power quality improvement", Int. Conf on Advancements in Power and Energy

(TAP Energy), pp. 327-332, 20 IS .

[2]

B. Singh and V. Verma, "An improved hybrid filter for compensation of

current and voltage harmonics for varying rectifier loads". Int. J.

Electrical Power & Energy Systems, Vol. 29, No. 4, pp. 312-xxx, May 2007.

[3]

H. Fujita, T. Yamasaki, and H. Akagi, " A hybrid active filters for damping

of harmonic resonance in industrial power system," IEEE Trans. on Power

Electrics, Vol IS , No. 2, pp. 209-216, 2000.

[4]

F.Z. Peng, H. Akagi, and A. Nanbe, " A new approach to harmonic compensation

in power systems-A combined system of shunt passive and series active

filters," I EEE Trans. on Ind. Appt, Vol. 26, pp. 983-990, Nov. 1990

[5]

B. Singh and V. Verma, "Design and Implementation of a Current Controlled

Parallel Hybrid Power Filter" Int. Conf on Power Electronics, Drives and

Energy Systems, PEDES'06, pp. 1-7, 2006.