ABSTRACT:

This

study presents the reduced sensors based standalone solar photovoltaic (PV)

energised water pumping. The system is configured to reduce both cost and

complexity with simultaneous assurance of optimum power utilisation of PV

array. The proposed system consists of an induction motor-operated water pump,

controlled by modified direct torque control. The PV array is connected to the

DC link through a DC–DC boost converter to provide maximum power point tracking

(MPPT) control and DC-link voltage is maintained by a three-phase

voltage-source inverter. The estimation of motor speed eliminates the use of tacho

generator/encoder and makes the system cheaper and robust. Moreover, an attempt

is made to reduce the number of current sensors and voltage sensors in the

system. The proposed system constitutes only one current sensor and only one voltage

sensor used for MPPT as well as for the phase voltage estimation and for the

phase currents’ reconstruction. Parameters adaptation makes the system stable

and insensitive toward parameters variation. Both simulation and experimental results

on the developed prototype in the laboratory validate the suitability of

proposed system.

SOFTWARE: MATLAB/SIMULINK

CIRCUIT DIAGRAM:

Fig. 1 circuit diagram (a) Proposed system,

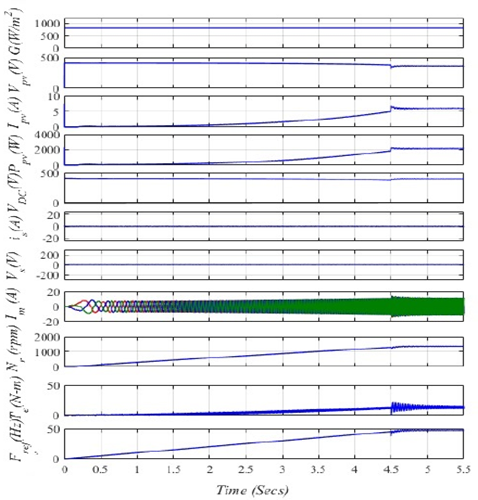

Fig. 2 Performance indices (a) PV array during starting to steady state at 1000 W/m2, (b) IMD indices at 1000 W/m2

Fig. 3 Performance

indices during insolation change 1000–500 W/m2

(a) PV

array, (b) IMD

indices 500–1000 W/m2, (c) PV array (d) IMD indices

Fig. 4 Adaptation

mechanism

(a) Rs

adaptation at rated speed and insolation, (b) τr Adaptation at rated speed and

rated insolation

Fig. 5 Performance

indices of the drive

(a) Starting

at 1000 W/m2, (b) Starting

at 500 W/m2, (c) Steady

state at 1000 W/m2,

(d) Steady state at 500 W/m2

Fig. 6 Dynamic

performance of the drive under variable insolation

(a) 1000–500

W/m2, (b) 500–1000

W/m2, (c) Intermediate

speed signals at 1000–500

W/m2, (d) Intermediate speed signals at 500–1000 W/m2

Fig. 7 Intermediate

signals in terms of

(a) Te* and Te at 1000–500 W/m2, (b) 500–1000 W/m2, (c) Reference stationary

components of flux and estimated

flux at 1000–500 W/m2, (d) 500–1000 W/m2

Fig. 8 Reconstructed

and measured current waveforms of phases a and b

at

(a) Starting

performance at 1000 W/m2, (b) 1000 W/m2, (c) 500 W/m2, (d) Boost

converter parameters at 1000 W/m2

CONCLUSION:

The modelling and simulation of the

proposed system has been carried out in MATLAB/Simulink and its suitability is

validated experimentally on a developed prototype in the laboratory. The system

comprises of one voltage sensor and one current sensor, which are sufficient

for the proper operation of the proposed system. The motor-drive system

performs satisfactorily during starting at various insolations, steady-state,

dynamic conditions represented by changing insolation. The speed estimation has

been carried out by flux components in stationary frame of reference. The flux

and torque are controlled separately. Therefore, successful observation of the

proposed system with satisfactory performance has been achieved without the

mechanical sensors. This topology improves the stability of the system. The

stability of the system at rated condition toward stator resistance variation

is shown by Nyquist stability curve and the stability toward the rotor-time constant

perturbation is shown by Popov's criteria. The DTC of an induction motor with

fixed frequency switching technique reduces the torque ripple. The line

voltages are estimated from this DC-link voltage. Moreover, the reconstruction

of three-phase stator currents has been successfully carried out from DC-link

current. Simulation results are well validated by test results. Owing to the

virtues of simple structure, control, cost-effectiveness, fairly good

efficiency and compactness, it is inferred that the suitability of the system

can be judged by deploying it in the field.

REFERENCES:

[1] Masters, G.M.: ‘Renewable and efficient

electric power systems’

(IEEE Press,Wiley and Sons, Inc., Hoboken, New Jersey, 2013), pp. 445–452

[2] Foster, R., Ghassemi, M., Cota,

M.: ‘Solar energy: renewable

energy and the environment’

(CRC Press, Taylor and Francis Group, Inc., Boca Raton, Florida, 2010)

[3] Parvathy, S., Vivek, A.: ‘A

photovoltaic water pumping system with high efficiency and high lifetime’. Int.

Conf. Advancements in Power and Energy (TAP Energy), Kollam, India, 24–26 June

2015, pp. 489–493

[4] Shafiullah, G.M., Amanullah,

M.T., Shawkat Ali, A.B.M.,

et al.: ‘Smart grids: opportunities,

developments and trends’

(Springer, London, UK, 2013)

[5] Sontake, V.C., Kalamkar, V.R.:

‘Solar photovoltaic water pumping system – a comprehensive review’, Renew. Sustain. Energy Rev., 2016, 59, pp. 1038– 1067