ABSTRACT:

In this paper, methods for sizing of PV pumping systems

and the simulation of (DTC) Direct Torque Control of induction motor that is

used for piloting a water pump supplied by a photovoltaic generator are

presented. The sizing of the PV pumping system is based on the calculation of

the water needs, the required hydraulic energy and the estimation of available

solar power. The best sizing of the PV pumping system may further help in

reducing its cost and optimize its efficiency. The proposed system includes a

solar panel, a DC/DC converter with MPPT control, a voltage inverter with pulse

width modulation (PWM). The Pump is driven by a Three Phase Induction Motor. In

order to control the water flow in the pump, Direct torque control of induction

machine is used. The simulations are carried out in Matlab/Simulink.

KEYWORDS:

1.

MPPT

2.

DTC

3.

PV pumping

4.

Photovoltaic

5.

Three phase

induction motor

6.

Induction

machine (IM)

7.

Voltage

inverter

8.

Pulse width

modulation (PWM)

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig. 1. System block diagram

Fig.

2. Band hysteresis of flux

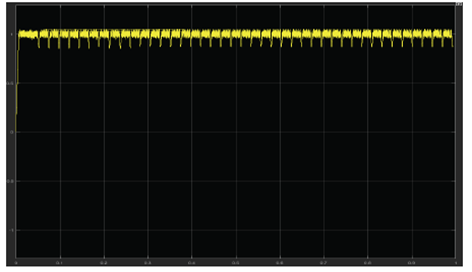

Fig. 3. Statoric Flux evolution

Fig.

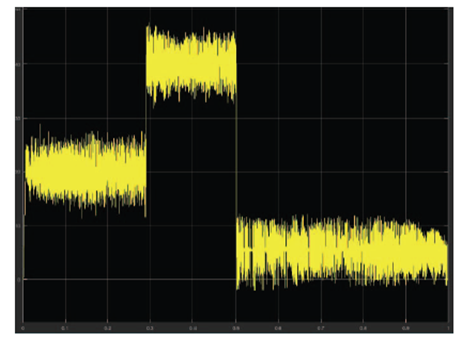

4. Electromagnetic Torque

Fig.

5. Stator current dq Axis

Fig.

6. The motor speed

CONCLUSION:

In

this paper, a case study of stand-alone PV pumping system designed for

irrigation needs in a remote site in Tunisia. The sizing method for the

structure was presented. MPPT technique was used to optimize the power

delivered by the photovoltaic module. Direct torque control technique served to

control the induction machine speed and therefore the flow of the centrifugal

pump. The paper presented the system block diagram, the MPPT control algorithm,

the DTC block diagram and design. The main objective of this work is to

maximize savings in energy consumption by ensuring that pipelines and networks

are sized and designed accurately. The use of DTC technique ensures better

efficiency of the motor. The experimental results are satisfactory and suggest

that the proposed solution can be a reliable option to overcome the lack of

electricity at remote locations and rural areas. More reliability test and

studies needs to be performed to guarantee its robustness, efficiency and cost

effectiveness.

REFERENCES:

[1]

“Solar resource maps for Tunisia”, Solargis S.R.O Slovakia, Maps.

[2]

Chaabane. M, Ben Djemaa. A. and Kossentini, “A daily and hourly global

irradiations in Tunisia extracted from Meteosat Wedax images”, Solar Energy,

vol. 57, issue 6, pp. 449-457.

[3]

Information obtained from the direction of the bureau of organic farming, CRDA

Tozeur.

[4]

T. Augustyn. “Energy efficiency and savings in pumping systems, The holistic

approach”, Energy Efficiency Convention (SAEEC), 2012 Southern African.

[5]

Jim McGovern, “Technical Note: Friction Factor Diagrams for Pipe Flow”, Dublin

Institute of Technology, 2011.