This paper aims at the design, control and implementation

of a solar photovoltaic (PV) array fed speed sensorless direct torque control

(DTC) of an induction motor drive (IMD) for water pumping in standalone as well

as battery connected hybrid mode. This stator flux estimated by proposed flux

observer, is used for speed estimation. A DC link current sensor is used to

reconstruct the motor phase currents by modified active voltage vector. One

voltage sensor for DC link voltage sensing and only one current sensor for DC

link current sensing, are used in this system for standalone operation of the

system. All other required quantities are estimated through these two sensed signals.

The IMD is energized by a photovoltaic (PV) array, which is operated at maximum

power point (MPP). A perturb and observe control algorithm with additional flow

rate controller, is proposed for MPP, which tracks MPP throughout the operating

range and provides the facility to control flow rate. The suitability of the

system is judged through simulated results in MATLAB/Simulink as well as test

results obtained on a prototype developed in the laboratory.

KEYWORDS:

1.

PV Array

2.

Single Stage System

3.

Perturb and Observe (P&O) Algorithm

4.

Direct Torque Control (DTC)

5.

Speed Sensorless

6.

Current Reconstruction

7.

Induction Motor

8.

Submersible Water Pump

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig.

1 Scheme of proposed PV-battery system

EXPECTED SIMULATION RESULTS:

Fig.

2 Bode plot showing the frequency response of flux observer with the

conventional

technique

(a) (b)

Fig.

3 Performance indices: (a) PV array during starting to steady-state at

1000W/m2

(b) IMD indices at 1000W/m2

(a)

(b)

(c) (d)

(e)

(f)

Fig.

4 Performance indices during insolation change (a) PV array:1000W/m2-

500W/m2

(b) Induction motor drive:1000W/m2-500W/m2 (c) PV array:

500W/m2-1000W/m2

(d) Induction motor drive: 500W/m2-1000W/m2

(e)

PV array:100W/m2-1000W/m2 (f) Induction motor drive:

100W/m2-1000W/m2

(a) (b)

(c)

(d)

Fig.

5 Simulation results at rated insolation and (a) Rated flow rate (b) 80%

of

rated flow rate (c) 60% of rated flow rate (d) 40% of rated flow rate

Fig.

6 Stator flux trajectory at rated condition of proposed system

(a) (b)

(c)

Fig.

7 Performance parameters of hybrid system (a) PV parameters (S, Vdc,

Vpv,

Ipv) (b) Battery indices (Vdc, SOC, Vbat, Ibat)

(c) Motor indices

(a)

(b)

(c)

Fig.

8 Performance parameters during battery charging of hybrid system (a)

PV

parameters (S, Vdc, Vpv, Ipv) (b) Battery indices (Vdc,

SOC, Vbat, Ibat)

(c)

Motor indices

Fig.

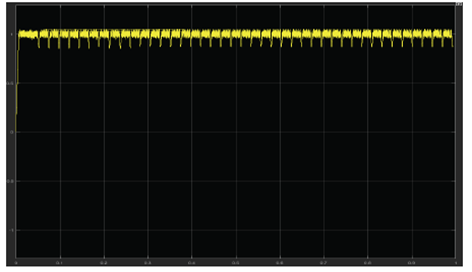

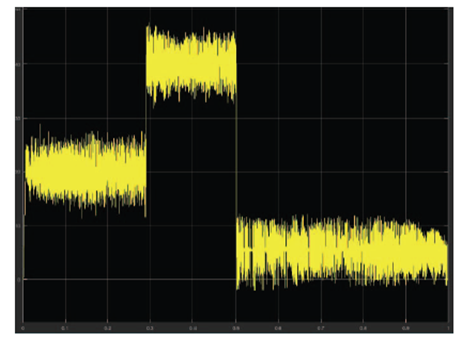

9 Starting performance of the drive: (a) 1000W/m2 (b) 500W/m2

CONCLUSION:

The

proposed solar PV array fed water pumping system has been modeled and simulated

in MATLAB/Simulink in standalone and PV array-battery connected modes, and its suitability

is studied experimentally on a prototype in the laboratory. In standalone mode

with PV array feeding water pump, the system comprises of one voltage sensor

and one current sensor, which are sufficient for the proper operation of proposed

system. Moreover, a P&O based MPPT with derating feature technique has been

proposed to regulate the flow rate by controlling the PV array power, thereby

enabling the user to operate the pump for any discharge and flow rate. The

motordrive system performs satisfactorily during starting at various insolations,

steady-state, dynamic conditions represented by changing insolation. The speed

is estimated in stationary flux components by flux observer, which has been

used for DC offset rejection as well as for the satisfactory operation at lower

frequency. The flux and torque, are controlled separately. The direct torque

control (DTC) is achieved with fixed frequency switching technique for reducing

the torque ripple. The line voltages are estimated from this DC link voltage.

Moreover, the reconstruction of three phase stator currents, has been successfully

carried out from DC link current. In addition, a smooth changeover facility

from DTC to scalar control has been provided to ensure the uninterrupted

performance of the system even though the current sensor fails. The switching

signals are generated by space vector modulation technique (SVM) to drive three

phase VSI, which has offered less harmonics distortion (THD) in motor currents

as compared with SPWM technique. Simulation results are well validated by experimental

results. In the second mode, a successful implementation of bidirectional power

flow between PV arraybattery connected systems has been achieved and its

suitability has been checked at various conditions. Owing to the virtues of simple

structure, control, cost-effectiveness, fairly good efficiency and compactness,

it can be inferred that the suitability of the system can be judged by

deploying it in the field.

REFERENCES:

[1] G. M. Masters, Renewable and efficient electric

power systems, IEEE Press, Wiley and Sons, Inc. 2013, pp. 445-452.

[2] R. Foster, M. Ghassemi and M. Cota, Solar

energy: Renewable energy and the environment, CRC Press, Taylor and Francis

Group, Inc. 2010.

[3] S. Parvathy and A. Vivek, “A photovoltaic water

pumping system with high efficiency and high lifetime,” Int. Conf.

Advancements in Power and Energy (TAP Energy), pp.489-493, 24-26 June 2015.

[4] G. M. Shafiullah, M. T. Amanullah, A. B. M.

Shawkat Ali, P. Wolfs, and M. T. Arif, Smart Grids: Opportunities, Developments

and Trends. London, U.K.: Springer, 2013.

[5] Vimal Chand Sontake and Vilas R. Kalamkar, “Solar

photovoltaic water pumping system - A comprehensive review,” Renewable and

Sustainable Energy Reviews, vol. 59, pp. 1038-1067, June 2016.