A High-Efficiency

Wide-Input-Voltage Range Switched Capacitor Point-of-Load DC–DC Converter

ABSTRACT:

The traditional inductor-based buck converter has been

the default design for switched-mode voltage regulators for decades. Switched

capacitor (SC) dc–dc converters, on the other hand, have traditionally been

used in low-power (<10 mW) and low conversion ratio (<4:1)

applications where neither regulation nor efficiency is critical. This study

encompasses the complete successful design, fabrication, and test of a

CMOS-based SC dc–dc converter, addressing the ubiquitous 12–1.5 V board mounted

point-of-load application. In particular, the circuit developed in this study

attains higher efficiency (92% peak, and >80% over a load range of 5

mA to 1 A) than surveyed competitive buck converters, while requiring less

board area and less costly passive components. The topology and controller

enable a wide input range of 7.5–13.5 V. Controls based on feedback and feed forward

provide tight regulation under worst case line and load step conditions. This

study shows that the SC converter can outperform the buck

converter,

and thus, the scope of SC converter application can and should be expanded.

KEYWORDS:

1. DC-DC power converters

2. switched

capacitor circuits

3. switched-mode power supply

SOFTWARE: MATLAB/SIMULINK

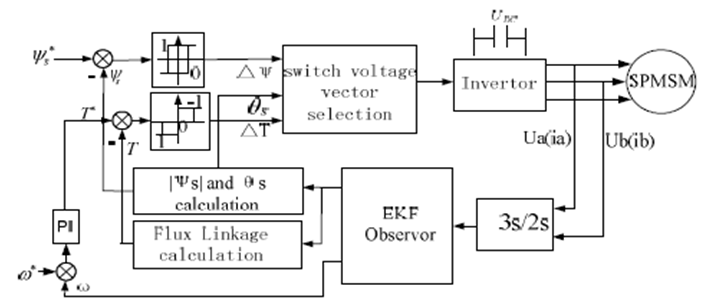

BLOCK DIAGRAM:

Fig. 1. Overall block diagram of the controller.

CONCLUSION:

The

traditional inductor-based buck converter has been the default design for

switched-mode voltage regulators for decades. Switched capacitor (SC) dc–dc

converters, on the other hand, have traditionally been used in low-power (<10

mW) and low conversion ratio (<4:1) applications where neither

regulation nor efficiency is critical. This study encompasses the complete successful

design, fabrication, and test of a CMOS-based SC dc–dc converter, addressing

the ubiquitous 12–1.5 V board mounted point-of-load application. In particular,

the circuit developed in this study attains higher efficiency (92% peak, and >80%

over a load range of 5 mA to 1 A) than surveyed competitive buck converters,

while requiring less board area and less costly passive components. The

topology and controller enable a wide input range of 7.5–13.5 V. Controls based

on feedback and feed forward provide tight regulation under worst case line and

load step conditions. This study shows that the SC converter can outperform the

buck converter, and thus, the scope of SC converter application can and should

be expanded.

REFERENCES:

[1]

M. Seeman and S. Sanders, “Analysis and optimization of switched capacitor dc–dc

converters,” IEEE Trans. Power Electron., vol. 23, no. 2, pp. 841–851,

Mar. 2008.

[2]

M. Seeman,V.Ng, H.-P. Le,M. John, E. Aton, and S. Sanders, “Acomparative analysis

of switched-capacitor and inductor-based dc–dc conversion technologies,” in Proc.

IEEE Workshop Control Model. Power Electron. (COMPEL), Jun. 2010.

[3]

M. Seeman, “A design methodology for switched-capacitor dc-dc converters,” Ph.D.

dissertation, UC Berkeley, Berkeley, CA, May 2009.

[4]

High Efficiency, 250 mA Step-Down Charge Pump, Texas Instruments (TPS60503),

Dallas, TX, 2002.

[5]

500 mA High Efficiency, Low Noise, Inductor-Less Step-Down DC/DC Converter,

Linear Technology (LTC3251), Milpitas, CA, 2003.