ABSTRACT:

In

this paper, the position sensorless direct torque and indirect flux control

(DTIFC) of BLDC motor with nonsinusoidal (non-ideal trapezoidal) back-EMF has

been extensively investigated using three-phase conduction scheme with

six-switch inverter. In the literature, several methods have been proposed to

eliminate the low-frequency torque pulsations for BLDC motor drives such as

Fourier series analysis of current waveforms and either iterative or

least-mean-square minimization techniques. Most methods do not consider the stator

flux linkage control, therefore possible high-speed operations are not

feasible. In this work, a novel and simple approach to achieve a low-frequency

torque ripple-free direct torque control with maximum efficiency based on dq

reference frame similar to permanent magnet synchronous motor (PMSM) drives

is presented. The electrical rotor position is estimated using winding

inductance, and the stationary reference frame stator flux linkages and

currents. The proposed sensorless DTC method controls the torque directly and

stator flux amplitude indirectly using d–axis current. Since stator flux

is controllable, flux-weakening operation is possible. Moreover, this method

also permits to regulate the varying signals. Simple voltage vector selection

look-up table is designed to obtain fast torque and flux control. Furthermore,

to eliminate the low-frequency torque oscillations, two actual and easily

available line-to-line back- EMF constants (kba and kca)

according to electrical rotor position are obtained offline and converted to

the dq frame equivalents using the new Line-to-Line Park Transformation.

Then, they are set up in the look-up table for torque estimation. The validity and

practical applications of the proposed three-phase conduction DTC of BLDC motor

drive scheme are verified through simulations and experimental results.

KEYWORDS:

1. Brushless

dc (BLDC) motor

2. Position sensorless control

3. Direct

torque control (DTC)

4. Stator flux control

5. Fast torque response

6. Non-sinusoidal back-EMF

7. Low frequency torque ripples

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

EXPECTED SIMULATION RESULTS:

Fig.

2. Simulated indirectly controlled stator flux linkage trajectory under the sensorless

three-phase conduction DTC of a BLDC motor drive when is changed from 0 A to -5 A under 0.5 N·m

load torque.

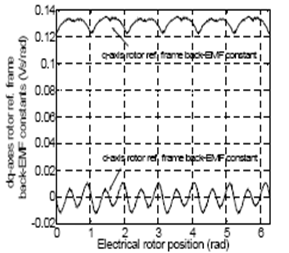

Fig.

3. Actual q– and d–axis rotor reference frame back-EMF constants versus

electrical rotor position and

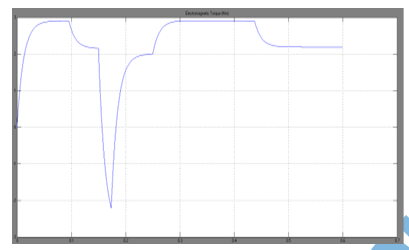

Fig.4.

Steady-state and transient behavior of the experimental (a) q–axis

stator current, (b) d–axis stator current, (c) estimated electromagnetic

torque and (d) ba–ca frame currents when under 0.5 N·m load torque.

Fig.

5. Experimental indirectly controlled stator flux linkage trajectory under the

sensorless three-phase conduction DTC of a BLDC motor drive when at 0.5 N·m load torque.

Fig.

6. Steady-state and transient behavior of the actual and estimated electrical

rotor positions from top to bottom, respectively under 0.5 N·m load torque.

CONCLUSION:

This

study has successfully demonstrated application of the proposed position

sensorless three-phase conduction direct torque control (DTC) scheme for BLDC

motor drives. It is shown that the BLDC motor could also operate in the field weakening

field weakening region by properly selecting the d–axis current reference

in the proposed DTC scheme. First, practically available actual two

line-to-line back-EMF constants (%"# and %$#) versus electrical rotor position

are obtained using generator test and converted to the dq frame

equivalents usingthe new Line-to-Line Park Transformation in which only two input

variables are required. Then, they are used in the torque estimation algorithm.

Electrical rotor position required in the torque estimation is obtained using

winding inductance, stationary reference frame currents and stator flux

linkages. Since the actual back-EMF waveforms are used in the torque

estimation, low-frequency torque oscillations can be reduced convincingly

compared to the one with the ideal trapezoidal waveforms having 120 electrical

degree flat top. A look-up table for the three-phase voltage vector selection

is designed similar to a DTC of PMSM drive to provide fast torque and flux

control. Because the actual rotor flux linkage is not sinusoidal, stator flux

control with constant reference is not viable anymore. Therefore, indirect

stator flux control is performed by controlling the flux related d–axis

current using bang-bang (hysteresis) control which provides acceptable control

of time-varying signals (reference and/or feedback) quite well. Since the

proposed DTC scheme does not involve any PWM strategies, PI controllers as well

as inverse Park and Clarke Transformations to drive the motor, much simpler overall

control is achieved.

REFERENCES:

[1]

I. Takahashi and T. Noguchi, “A new quick-response and high efficiency control

strategies of an induction motor,” IEEE Trans. Ind. Appl., vol.

22, no. 5, pp. 820–827, Sep./Oct. 1986.

[2]

M. Depenbrock, “Direct self-control of inverter-fed induction machine,” IEEE

Trans. Power Electron., vol. 3, no. 4, pp. 420–429, Oct. 1988.

[3]

L. Zhong, M. F. Rahman, W. Y. Hu, and K. W. Lim, “Analysis of direct torque

control in permanent magnet synchronous motor drives,” IEEE Trans. Power

Electron., vol. 12, no. 3, pp. 528–536, May 1997.

[4]

Y. Liu, Z. Q. Zhu, and D. Howe, “Direct torque control of brushless dc drives

with reduced torque ripple,” IEEE Trans. Ind. Appl., vol. 41, no. 2, pp.

599–608, Mar./Apr. 2005.

[5]

S. B. Ozturk and H. A. Toliyat, “Direct torque control of brushless dc motor

with non-sinusoidal back-EMF,” in Proc. IEEE-IEMDC Biennial Meeting,

Antalya, Turkey, May 3-5, 2007.