ABSTRACT:

MATLAB

/ SIMULINK implementation of the Direct Torque Control Scheme for induction

motors is presented in this paper. Direct Torque Control (DTC) is an advanced

control technique with fast and dynamic torque response. The scheme is

intuitive and easy to understand as a modular approach is followed. A

comparison between the computed and the reference values of the stator flux and

electromagnetic torque is performed. The digital outputs of the comparators are

fed to hysteresis type controllers. To limit the flux and torque within a

predefined band, the hysteresis controllers generate the necessary control signals.

The knowledge about the two hysteresis controller outputs along with the

location of the stator flux space vector in a two dimensional complex plane

determines the state of the Voltage Source Inverter (VSI). The output of the

VSI is fed to the induction motor model. A flux optimization algorithm is added

to the scheme to achieve maximum efficiency. The output torque and flux of the

machine in the two schemes are presented and compared

KEYWORDS:

1.Direct Torque

Control,

2. Induction Motor,

3. Flux Optimization

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Figure 1: Block Diagram of

Conventional DTC Scheme

Figure 2: Block Diagram of the

Flux Optimized DTC Scheme

EXPECTED SIMULATION RESULTS:

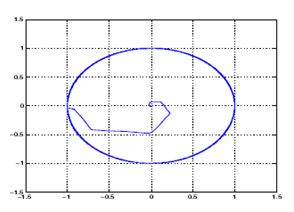

Figure 3: Stator d-q flux space vector without flux optimization

Figure 4: Stator d-q flux

space vector with flux optimization

Figure

5: Variation of Stator Flux – Conventional DTC Scheme

Fig 6: Variation of Stator Flux - Optimized DTC scheme

Figure 7: Variation of Mechanical

Speed – Conventional optimized DTC scheme

Figure 8:

Variation of Mechanical Speed - Optimized DTC scheme

Figure

9: Electromagnetic Torque - Conventional DTC

Figure 10: Electromagnetic Torque

- Optimized DTC

Figure 11:

Percentage Efficiency of Flux Optimized DTC

CONCLUSION:

In

this paper, DTC for an induction motor drive has been shown along with flux

optimization algorithm. DTC is a high performance, robust control structure. A

comparative analysis of the two DTC schemes, with and without flux optimization

algorithm has been presented. With flux optimization implementation, it is

observed that the efficiency of the about 87 % has been obtained. MATLAB

simulation of a 15 Hp IM drive has been presented to confirm the results.

REFERENCES:

[1]

Werner Leonhard. Control of Electric

Drives. Springer-Verlag Berlin Heidelberg, 1996.

[2]

F. Blaschke. “The Principle of Field Orientation as Applied to The New Transvector

Closed Loop Control System for Rotating Field Machines”. Siemens Review, pages 217–220, 1972.

[3]

K. Hasse. “On The Dynamic Behavior of Induction Machines Driven by Variable

Frequency and Voltage Sources”. ETZ

Archive, pages 77–81., 1968.

[4]

I. Takahashi and T Nogushi. “A New Quick Reponse and High Efficiency Control

Strategy of an Induction Motor”. IEEE

Trans. Industry Applications,

IA -22:820–827, 1986.

[5]

M. Depenbrock. “Direct Self Control (DSC) of inverter-fed induction machines”. IEEE Trans. Power Electronics,

3(4):420–429, 1988