Enhancement of Voltage Quality

in Isolated Power Systems

ABSTRACT

The use of series compensators (SCs) in improving voltage

quality of isolated power systems is considered. The roles of the compensators

are to mitigate the effects of momentary voltage sags/swells, and to control

the level of harmonic distortions in the networks. A control strategy for the

SC is developed to regulate power flow. This is achieved through phase

adjustment of load terminal voltage. It leads to an increase in the ride through

capability of loads to the voltage sags/swells. Validity of the technique is

illustrated through simulation.

KEYWORDS

1.

Harmonic power

flow

2.

Isolated power

system

3.

phase shift

4.

Series compensation

SOFTWARE:

Matlab/Simulink

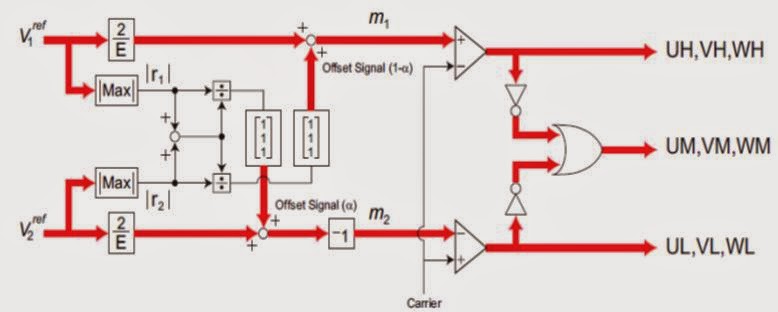

BLOCK DIAGRAM:

Fig.

1.Typical isolated power system installed with an SC.

CONCLUSION:

Voltage

quality improvement in an isolated power system through series compensation has

been investigated. The power system contains significant proportion of

fluctuating nonlinear load and a high level of harmonic distortions is

observed. A method to control the injection voltage of the SC so that it can mitigate

the effects of the harmonics has been proposed. The SC is also designed to

maintain the fundamental frequency component of the terminal voltage of

protected sensitive load. In the process of harmonic voltage compensation, it

is shown that power exchange exists between the SC and the external network. Based

on the analysis of the harmonic real power flow in the power system, it is seen

that the SC would import harmonic real power from the external system. A new SC

control strategy is then proposed which involves the phase adjustment of the

fundamental frequency component of the sensitive load terminal voltage. Through

the analysis on the power exchange it is shown that the load ride through

capability during voltage sag can be improved with the support of the harmonic

real power absorbed by the SC. The capacity of the SC required is modest and,

therefore, makes it a viable device for such an application. Simulations have

confirmed the effectiveness of the proposed method, as it is applied on the SC

to achieve improved quality of supply in the power system.

REFERENCES:

[1]

I. Jonasson and L. Soder, “Power quality on ships-a questionnaire evaluation concerning

island power system,” in Proc. IEEE Power Eng. Soc. Summer Meeting,

Jul. 2001, vol. 15–19, pp. 216–221.

[2]

J. J. Graham, C. L. Halsall, and I. S. McKay, “Isolated power systems: Problems

of waveform distortion due to thyristor converter loading,” in Proc. 4th

Int. Conf. Power Electronics and Variable-Speed Drives, Jul. 1990, vol.

17–19, pp. 327–330.

[3]

ITI (CBEMA) Curve Application Note, [Online]. Available: http://www.itic.org.,

Inf. Technol. Ind. Council (ITI).

[4]

J. C. Das, “Passive filter—Potentialities and limitations,” IEEE Trans. Ind.

Appl., vol. 40, no. 1, pp. 232–241, Jan. 2004.

[5]

H. Akagi, “New trends in active filter for power conditioning,” IEEE Trans.

Ind. Appl., vol. 32, no. 6, pp. 1312–1322, Nov. 1996.