Direct Torque Control Based on Space Vector Modulation with Adaptive

Stator Flux Observer for Induction Motors

ABSTRACT:

This

paper describes a combination of direct torque control (DTC) and space vector

modulation (SVM) for an adjustable speed sensor less induction motor (IM)

drive. The motor drive is supplied by a two-level SVPWM inverter. Using the IM

model in the stator – axes reference frame with stator current and flux vectors

components as state variables. In this paper, a conventional PI controller is

designed accordingly for DTC-SVM system. Moreover, a robust full-order adaptive

stator flux observer is designed for a speed sensor less DTC-SVM system and a

new speed adaptive law is given. By designing the observer gain matrix based on

state feedback control theory, the stability and robustness of the observer

systems is ensured. Finally, the effectiveness and validity of the proposed

control approach is verified by simulation results.

KEYWORDS:

1.

DTC

2.

Stator Flux Observer

3.

Torque Ripple

SOFTWARE: MATLAB/SIMULINK

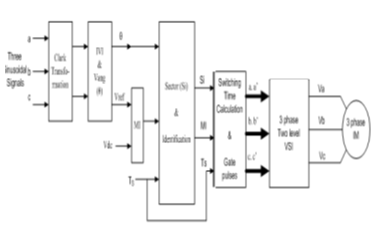

BLOCK DIAGRAM:

Fig. 1

Block Diagram of DTC-SVM system

CONCLUSION:

A

novel DTC-SVM scheme has been developed for the IM drive system, In this

control method, a SVPWM inverter is used to feed the motor, the stator voltage

vector is obtained to fully compensate the stator flux and torque errors.

Furthermore, a robust full-order adaptive flux observer is designed for a speed

sensor-less DTC-SVM system. The stator flux and speed are estimated synchronously.

By designing the constant observer gain matrix, the robustness and based on

state feedback stability of the observer systems is ensured. Therefore, the

proposed sensor-less drive system is capable of steadily working in very low

speed, has much smaller torque ripple and exhibits good dynamic and

steady-state performance.

REFERENCES:

[1] I. Takahashi

and T. Noguchi, “A new quick-response and high efficiency control strategy of

an induction motor,” IEEE Trans. Ind. Appl.,vol. IA-22, no. 5, pp. 820–827,

1986.

[2] Y. S. Lai and

J. H. Chen, “A new approach to direct torque control ofinduction motor drives

for constant inverter switching frequency andtorque ripple reduction,” IEEE

Trans. Energy Convers., vol. 16, no. 3,pp. 220–227, 2001.

[3] S. Mir, M. E. Elbuluk, and D. S. Zinger,

“PI and fuzzy estimators for tuning the stator resistance in direct torque

control of induction machines,” IEEE Trans. Power Electron., vol. 13, no. 2,

pp. 279–287,1998.

[4] F. Bacha, R.

Dhifaoui, and H. Buyse, “Real-time implementation ofdirect torque control of an

induction machine by fuzzy logic controller,” in Proc. ICEMS, 2001, vol. 2, pp.

1244–1249.

[5]

A. Arias, J. L. Romeral, and E. Aldabas, “Fuzzy logic direct torquecontrol,” in

Proc. IEEE ISIE, 2000, vol. 1, pp. 253–258.