ABSTRACT:

Control of induction motor is most precisely required

in many high performance applications. With the development in power electronic

field various control methods for control of induction motor have been

developed. Among these Direct torque control (DTC) seems to be particularly

interesting, being independent of machine rotor parameters and requiring no speed

or position sensors. In addition to the simple structure it also allows a good

torque control in transient and steady state conditions. The disadvantage of

using DTC is that it results in high torque and flux ripple and variable

switching frequency of voltage source inverter, owing to the use of hysteresis

controllers for torque and flux loop. In order to overcome these problems, various

methods have been proposed by several researchers like variable hysteresis band

comparators, space vector modulation, predictive control schemes and

intelligent control techniques. However these methods have diminished the main

feature of DTC that is simple control structure. This report presents constant

switching frequency based torque and flux controllers to replace conventional

hysteresis based controllers where almost fixed switching frequency with

reduced torque and flux ripple is obtained by comparing the triangular

waveforms with the compensated error signals

KEYWORDS:

1.3-phase VSI

2. torque controller

3.

flux controller

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig.1.

Block diagram of conventional DTC method

Fig.2. MATLAB/SIMULINK Model of

the DTC Drive

EXPECTED SIMULATION RESULTS:

Fig.3.

Torque response (a) Conventional DTC scheme (b) Improved DTC Scheme

Fig.4.

Speed and Torque response for (a) Conventional DTC scheme (b) Improved DTC

scheme

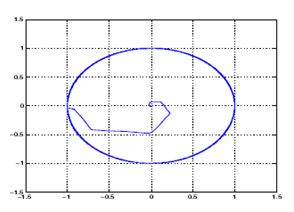

Fig.5.

Circular flux locus (a) conventional DTC scheme (b) Improved DTC scheme

Fig.6.

3-phase line-line voltages and currents (a) Conventional DTC scheme (b)

Improved DTC scheme

CONCLUSION:

In

this paper a detailed comparison between the conventional DTC and improved DTC

scheme is made with help of some Matlab simulation results and hence it is

shown that a significant reduction in torque and flux ripple can be achieved

with the improved DTC scheme also with improved controllers the switching

frequency which is constant can be varied by varying the frequency of the

triangular carrier waveforms of the torque controllers

REFERENCES:

[1] I. Takahashi and T. Noguchi, “A new quick-response and high efficiency

control strategy of an induction motor,” IEEE Trans. Ind. Appl., vol. IA-22,no. 5, pp. 820–827, Sep.–Oct.

1986.

[2] J-K. Kang, D-W Chung, S. K. Sul, (2001) “Analysis and

prediction of inverter switching frequency in direct torque control of

induction machine based on hysteresis bands and machine parameters”, IEEE Transactions on Industrial Electronics,

Vol. 48, No. 3, pp. 545-553.

[3] D.Casadei, G.Gandi,G.Serra,A.Tani,(1994)“Switching

strategies in direct torque control of induction machines,” in Proc. of ICEM’94, Paris (F), pp. 204-209.

[4] J-K. Kang, D-W Chung and S.K. Sul, (1999) “Direct torque

control of induction machine with variable amplitude control of flux and torque

hysteresis bands”, International Conference on Electric Machines and Drives

IEMD’99,pp.640-642.

[5] Vanja Ambrozic, Giuseppe S. Buja, and Roberto Menis, ”Band- Constrained Technique for Direct

Torque Control of Induction Motor”, IEEE Trans. On industrial electronics ,

vol. 51, no. 4, august 2004, pp.776-784