ABSTRACT:

Space vector pulse width modulation (SVPWM) has been

extensively utilized in the three-phase voltage source inverters (VSI) for the

benefit of fixed switching frequency, full utilization of DC bus voltage and

superior control. In recent times, SVPWM technique was applied for active power

filter (APF) control application, as the APF is nothing but of a current controlled

VSI. The conventional SVPWM based APF has high computational burden due to

complex trigonometric

calculations and sector identification involved to

generate the compensating signal, hence the response time for compensation is

slow. In this paper, an improved SVPWM technique based shunt APF is presented

based on the effective time concept. The effective time concept eliminates the

trigonometric calculations and sector identification, thereby it reduces the

computational effort. Simulation results demonstrate the efficacy of the APF with

the improved SVPWM based control strategy. The response time for compensation

is 0.02sec.

KEYWORDS:

1. SVPWM

2. Shunt APF

3. VSI

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM

Figure 1. Configuration of Improved SVPWM based

shunt APF

CIRCUIT DIAGRAM:

Figure 2. Proposed SVPWM control for APF topology

EXPECTED SIMULATION RESULTS:

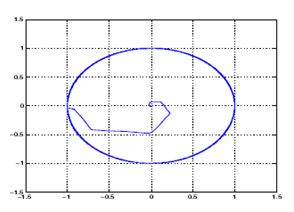

Figure 3.

Simulation results (a) Source voltages, (b) Load currents, (c) Compensated

source currents, and (d) Filter currents (APF).

Figure 4.DC Bus voltage

of the proposed shunt APF

CONCLUSION:

In this paper, an improved SVPWM based shunt

APF is proposed, which is suitable for digital control realization. This method

requires less computation when compared to the conventional SVPWM technique as

it eliminates the complex trigonometric calculation and sector identification,

The performance of shunt APF with this proposed SVPWM method for harmonic

compensation is examined and proved to be worthy where the THD of the source

currents was reduced

from 24.38% to 4.47% and the response time for harmonic compensation is 0.02

sec.

REFERENCES:

[1]

H. Akagi, E. H. Watanabe, and M. Aredes, Instantaneous Power Theory and

Applications to Power Conditioning, M. E. El-Hawari, Ed. New York:

Wiley, 2007.

[2]

Recommended Practice for Harmonic Control in Electric Power Systems, IEEE Std.

519-1992, 1992.

[3]

Limits for Harmonic Current Emission, IEC 61000-3-2, 2001.

[4]

H. Akagi, “New trends in active filters for power conditioning,” IEEE Trans.

Ind. Appl., vol. 32, no. 2, pp. 1312–1332, Nov./Dec. 1996.

[5]

F. Z. Peng, “Application issues of active power filters,” IEEE Ind. Appl.Mag.,

vol. 4, no. 5, pp. 21--30, Sep./Oct.

1998.