ABSTRACT

In this paper a Power Factor Correction Cuk converter

fed Brushless DC Motor Drive using a Artificial Neural Network is used. The

Speed of the Brushless dc motor is controlled by varying the output of the DC

capacitor. A Diode Bridge Rectifier followed by a Cuk converter is fed into a Brushless

DC Motor to attain the maximum Power Factor. Here we are evaluating the three

modes of operation in discontinuous mode and choosing the best method to

achieve maximum Power Factor and to minimize the Total Harmonic Distortion. We

are comparing the conventional PWM scheme to the proposed Artificial neural network.

Here simulation results reveal that the ANN controllers are very effective and

efficient compared to the PI and Fuzzy controllers, because the steady state

error in case of ANN control is less and the stabilization if the system is

better in it. Also in the ANN methodology the time taken for computation is

less since there is no mathematical model. The performance of the proposed

system is simulated in a MATLAB/Simulink environment and a hardware prototype

of the proposed drive is developed to validate its performance.

KEYWORDS:

1.

Brushless dc motor,

2.

Discontinuous input inductor mode

3.

Discontinuous output inductor mode

4.

Discontinuous intermediate capacitor mode

5.

Cuk converter

6.

Power Factor Correction

7.

Total Harmonic Distortion

8.

Artificial Neural Network

9.

Pulse width modulation

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig 1.Proposed Scheme using

Artificial Neural Network

EXPECTED SIMULATION RESULTS:

Fig 2.Simulation Waveforms a)

Input voltage (Vin) b) Input current (Iin) c) Output voltage(Vcd)

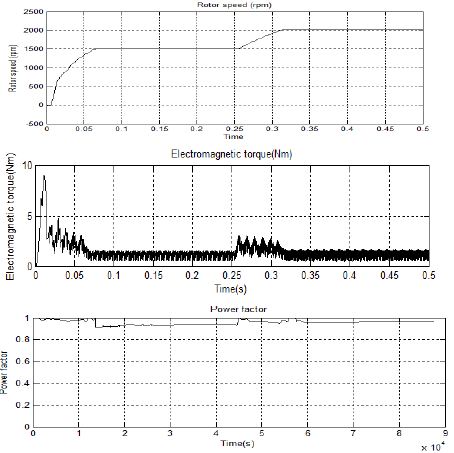

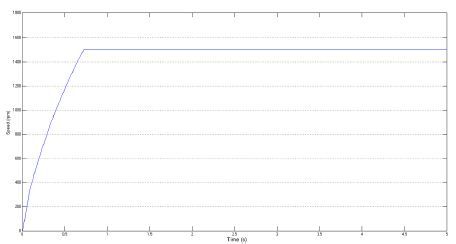

Fig.3

a)Speed(rpm) b)Electromagnetic torque(Nm) c)Power factor

Fig 4

Stator back emfs (Ea,Eb,Ec)

CONCLUSION

A

Power Factor Corrected Cuk converter fed BLDC motor using Artificial neural

network is simulated in the environment of MATLAB. A Diode Bridge Rectifier followed

by a Cuk converter is fed into a Brushless DC Motor to attain the maximum Power

Factor. Here we are evaluating the three modes of operation in discontinuous

mode and choosing the best method to achieve maximum Power Factor and to

minimize the Total Harmonic Distortion.The three modes Discontinuos

DICM(Li),DICM(Lo),DCVM(Vco) is simulated at the given switching frequency

20Khz.The diode bridge followed by a Cuk converter is used here for maximum Power

Factor Correction.The power factor obtaine in ANN is 0.9818 which is near to

unity. The main advantage of using Artificial neural network is that in

conventional PI only one value that is feed back is selected and comparing and producing

the gating pulse but in our proposed scheme a set of values is compared and we

are choosing the best out of them.

REFERENCES

[1] J.

F. Gieras and M.Wing, Permanent Magnet Motor Technology—Design and Application.

New York, NY, USA: Marcel Dekker, Inc, 2002.

[2] C.

L. Xia, Permanent Magnet Brushless DC Motor Drives and Controls.Beijing, China:

Wiley, 2012.

[3] Y.

Chen, C. Chiu, Y. Jhang, Z. Tang, and R. Liang, “A driver for the singlephase

brushlessDCfan motor with hybrid winding structure,” IEEE Trans.Ind. Electron.,

vol. 60, no. 10, pp. 4369–4375, Oct. 2013.

[4] S.

Nikam, V. Rallabandi, and B. Fernandes, “A high torque density permanent magnet

free motor for in-wheel electric vehicle application,” IEEE Trans. Ind. Appl.,

vol. 48, no. 6, pp. 2287–2295, Nov./Dec. 2012.

[5] X.

Huang, A. Goodman, C. Gerada, Y. Fang, and Q. Lu, “A single sided matrix

converter drive for a brushless DC motor in aerospace applications,” IEEE

Trans. Ind. Electron., vol. 59, no. 9, pp. 3542–3552, Sep. 2012..