ABSTRACT

This paper deals with a highly reliable electrical drive

utilizing the Brushless DC Motor (BLDC). The motor is fed by Voltage source

Inverter (VSI) with a dc-dc converter power factor correction circuit (PFC) as

the VSI’s predecessor. The Performance of two dc-dc converters (cuk and sepic

as PFC) are analyzed and the results are discussed to arrive at the best suited

converter. Fuzzy Logic Controller is used as the Intelligent Controller for the

BLDC motor. Reliable, low cost arrangement is thus provided to achieve unity

power factor and speed regulation with accuracy. The drive has been simulated

using the MATLAB/Simulink environment and the performance has been studied.

KEYWORDS:

1.

Brushless DC

Motor (BLDC)

2.

Power Quality

(PQ)

3.

Power factor

correction (PFC)

4.

Cuk converter

5.

Sepic

converter

6.

Fuzzy logic

controller (FLC).

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig. 1. Block diagram

SIMULINK

MODEL DIAGRAMS:

Fig. 2. PFC cuk fed BLDC

Fig. 3. PFC Sepic fed BLDC

EXPECTED SIMULATION RESULTS:

Fig. 4. Input power factor

Fig. 5. Cuk Converter Efficiency

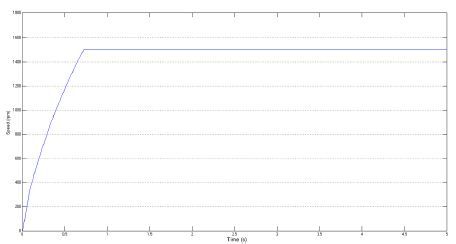

Fig. 6. Motor Speed

Fig. 7. Input power factor

Fig. 8. Sepic Converter Efficiency

Fig. 9. Motor Speed

CONCLUSION

The

power factor correction has been successfully implemented using the cuk and

sepic converter. It shows a much improved result as it not only provides better

power quality, but also the converter removes the necessity to smooth out the

dc output from ripples. The fuzzy logic controller widely increases application

range of the motor by increasing the reliability. The motor is presently used

in areas such as aerospace, aircraft and mining applications because of the enhanced

reliability that the motor offers. This is further enhanced by the usage of FLC

and the PFC converters. The FLC is used to control the motor speed and the cuk

or sepic converter is used for the power factor improvement. It is found that

the sepic converter is found to provide better power quality. The Analysis has

been done for Continuous conduction in the sepic and cuk converters as both are

not capable of self PFC.

REFERENCES

[1] R.Shanmugasundram,

K. Muhammad Zakariah and N. Yadaiah, “Implementation and Performance Analysis

of Digital Controllers for Brushless DC Motor Drives,” IEEE/ASME Trans.

Mechatronics, vol. 19, no. 1, Feb. 2014.

[2] T.

Kenjo and S. Nagamori, Permanent Magnet Brushless DC Motors.Oxford,

U.K.: Clarendon Press, 1985.

[3] Sanjeev

Singh and Bhim Singh, “A Voltage-Controlled PFC Cuk Converter-Based PMBLDCM

Drive for Air-Conditioners,” IEEE Trans. Ind. Appl. vol. 48, no. 2, Mar.

/Apr. 2012.

[4] Vashist

Bist and Bhim Singh, “PFC CUK Converter-Fed BLDC Motor Drive,” IEEE Trans.

Power Electron., vol. 30, no 2, Feb. 2015.

[5] “Limits

for harmonic current emissions (equipment input current≤16 A per

phase),” International Standard IEC 61000-3-2, 2000