Analysis And Design Considerations Of Zero-Voltage And

Zero-Current-Switching (ZVZCS) Full-Bridge PWM Converters

ABSTRACT

In this paper, a detailed

analysis of the zero voltage and zero-current-switching (ZVZCS) full-bridge PWM

converters is performed. The differences of the zero-voltage-switching (ZVS)

operation between the conventional ZVS full-bridge PWM converters and the ZVZCS

full-bridge PWM converters are analyzed in depth. Circuit parameters that

affect the soft-switching conditions are examined and the critical parameters

are identified. Based on the analysis, practical design considerations are

presented. The analysis and design considerations are verified by experimental results

from a 630V/4kW converter operating at 80kHz.

SOFTWARE: MATLAB/SIMULINK

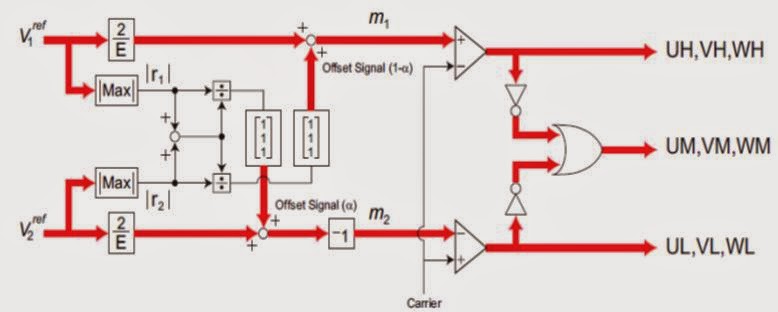

CIRCUIT DIAGRAM:

Fig. 1 Circuit diagram of

ZVZCS FB PWM converter

Fig.2 schematic of the converter

CONCLUSION:

In

this paper, the zero-voltage and zero-current-switching (ZVZCS) Full-bridge PWM

converter was analyzed in depth. The difference of the zero-voltage-switching

(ZVS) principle between the conventional ZVS full-bridge PWM converters and the

ZVZCS full-bridge PWM converters was analyzed in detail. Circuit parameters

affecting the soft switching conditions were examined and the critical parameters

were identified. Based on the analysis, practical design considerations were

presented. The design procedures can be applied to the various kinds of ZVZCS full-bridge

PWM converters [1-5]. The analysis and design considerations were verified by

experimental results from a 630V/4kW converter operating at 80kHz.

REFERENCES:

[1]

E. S. Kim, K. Y. Cho, et. Al., "An improved ZVZCS PWM FB DC/DC converter

using energy recovery snubber," IEEE APEC Rec., 1997, pp.1014-1019.

[2]

Jung G. Cho, Ju W. Baek, D.W. Yoo, Hong S. Lee, and Geun H. Rim, "Novel

Zero-Voltage and Zero-Current- Switching(ZVZCS) Full Bridge PWM Converter Using

Transformer Auxiliary Winding", IEEE PESC Rec., 1997, pp. 227-232.

[3]

Jung G. Cho, J. W. Baek, D.W. Yoo, H. S. Lee, and G. H. Rim, "Novel

Zero-Voltage and Zero-Current- Switching(ZVZCS) Full Bridge PWM Converter Using

a simple auxiliary circuit", IEEE APEC Rec., 1998, pp.834-839.

[4]

E. S. Kim, K.Y. Joe and S. G. Park, "An Improved ZVZCS PWM FB DC/DC

Converter Using the Modified Energy Recovery Snubber", IEEE APEC Rec., 2000,

pp.119-124.

[5]

H. S. Choi, J. W. Kim and B.H. Cho, “Novel-Zero- Voltage and

Zero-Current-Switching(ZVZCS) Full- Bridge PWM Converter Using Coupled Output Inductor”,

APEC 2001. pp.967-973