ABSTRACT:

To design a control system it is desirable to

represent the actual system in mathematical form. So a mathematical representation

of a permanent magnet synchronous motor is presented here. The inductances of a

PMSM vary as a function of rotor position, the d-q model is commonly used to

represent PMSM. The d-q model is obtained to implement the current control in

rotor reference frame. A fuzzy logic based speed controller for permanent

magnet synchronous motor is proposed and investigated. In the paper the dynamic

response of PMSM drive with proposed controller is analyzed for different

loading conditions and with various speed.

KEYWORDS:

1.

FLC

2.

Mathematical model

3.

PI controller

4.

PMSM

5.

SVM

SOFTWARE: MATLAB/SIMULINK

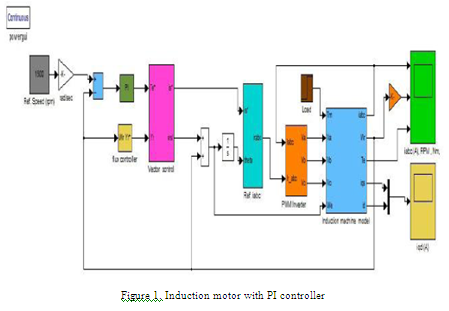

BLOCK DIAGRAM:

EXPECTED SIMULATION RESULTS:

CONCLUSION:

A

mathematical modeling of PMSM is presented here and d-q model is obtained to

implement the current control in rotor reference frame. In this paper

performance of a FLC is investigated to speed control of PMSM. FLC is designed

with three scaling factors (two inputs & one output) for setting the controller

parameter according to actual system. Tuning of these scaling factors is done

based on the parameter of motor and intervals for which membership functions

are defined. Performance of proposed FLC with gain tuning is found good in all

operating conditions.

REFERENCES:

[1] M. Kadjoudj, M. E. H. Benbouzid, C.

Ghennai, and D. Diallo, "A robust hybrid current control for permanent-magnet

synchronous motor drive," IEEE Transactions on Energy

Conversion, vol. 19, pp. 109- 115, 2004.

[2]

Y. Baudon, D. Jouve, and J. P. Ferrieux, "Current control of permanent

magnet synchronous machines. Experimental and simulation study," IEEE

Transactions on Power Electronics, vol. 7, pp. 560- 567, 1992.

[3]

B. K. Bose, Modern power electronics and AC drives: Prentice Hall PTR

USA, 2002.

[4]

R. H. Park, "Two-reaction theory of synchronous machines-II," Transactions

of theAmerican Institute of Electrical Engineers, vol. 52, pp.

352-354, 1933.

[5]

P. Vas, Sensorless vector and direct torque control vol. 729: Oxford

university press Oxford, UK, 1998.