ABSTRACT:

Hybrid

boost converter (HBC) has been proposed to replace a dc/dc boost converter and

a dc/ac converter to reduce conversion stages and switching loss. In this

paper, control of a three-phase HBC in a PV charging station is designed and

tested. This HBC interfaces a PV system, a dc system with a hybrid plugin electrical

vehicles (HPEVs) and a three-phase ac grid. The control of the HBC is designed

to realize maximum power point tracking (MPPT) for PV, dc bus voltage

regulation, and ac voltage or reactive power regulation. A test bed with power

electronics switching details is built in MATLAB/SimPowersystems for validation.

Simulation results demonstrate the feasibility of the designed control

architecture. Finally, lab experimental testing is conducted to demonstrate

HBC’s control performance.

KEYWORDS:

1. Plug-in

hybrid vehicle (PHEV)

2. Vector

Control

3. Grid-connected

Photovoltaic (PV)

4. Three-phase

Hybrid Boost Converter

5. Maximum

Power Point Tracking (MPPT)

6. Charging

Station

SOFTWARE: MATLAB/SIMULINK

Fig.

1. Topology of the three-phase HBC-based PV charging station.

EXPECTED SIMULATION RESULTS:

Fig.

2. Performance of a modified IC-PI MPPT algorithm when solar

irradiance

variation is applied.

Fig.

3. Performance of the dc voltage control in the vector control. The solid lines

represent the system responses when the dc voltage control is enabled. The

dashed lines represent the system responses when the dc voltage control

is

disabled.

Fig.

4. Performance of a proposed vector control to supply or absorb reactive power

independently.

Fig.

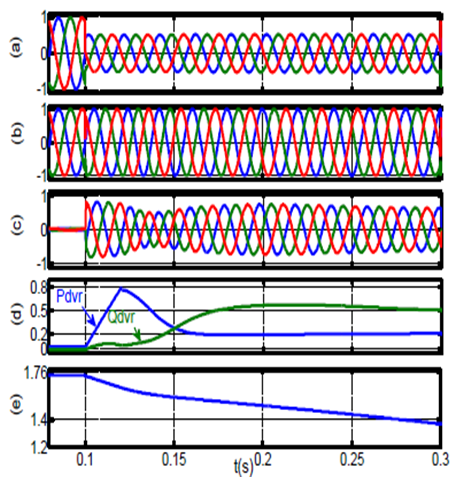

5. Power management of PV charging station.

Fig.

6. Dst, Md and Mq for case 4.

Fig.

7. System performance under 70% grid’s voltage drop.

CONCLUSION:

Control

of three-phase HBC in a PV charging station is proposed in this paper. The

three-phase HBC can save switching loss by integration a dc/dc booster and a

dc/ac converter converter into a single converter structure. A new control for

the three-phase HBC is designed to achieve MPPT, dc voltage regulation and

reactive power tracking. The MPPT control utilizes modified incremental conductance-PI

based MPPT method. The dc voltage regulation and reactive power tracking are

realized using vector control.

Five case studies are conducted in computer

simulation to demonstrate the performance of MPPT, dc voltage regulator, reactive

power tracking and overall power management of the PV charging station.

Experimental results verify the operation of the PHEV charging station using

HBC topology. The simulation and experimental results demonstrate the

effectiveness and robustness of the proposed control for PV charging station to

maintain continuous dc power supply using both PV power and ac grid power.

REFERENCES:

[1]

M. Ehsani, Y. Gao, and A. Emadi, Modern electric, hybrid electric, and fuel

cell vehicles: fundamentals, theory, and design. CRC press, 2009.

[2]

K. Sikes, T. Gross, Z. Lin, J. Sullivan, T. Cleary, and J. Ward, “Plugin hybrid

electric vehicle market introduction study: final report,” Oak Ridge National

Laboratory (ORNL), Tech. Rep., 2010.

[3]

A. Khaligh and S. Dusmez, “Comprehensive topological analysis of conductive and

inductive charging solutions for plug-in electric vehicles,” IEEE Transactions

on Vehicular Technology, vol. 61, no. 8, pp. 3475– 3489, 2012.

[4]

T. Anegawa, “Development of quick charging system for electric vehicle,” Tokyo

Electric Power Company, 2010.

[5]

F. Musavi, M. Edington, W. Eberle, and W. G. Dunford, “Evaluation and

efficiency comparison of front end ac-dc plug-in hybrid charger topologies,”

IEEE Transactions on Smart grid, vol. 3, no. 1, pp. 413–421, 2012.