Study of Induction Motor Drive with Direct Torque Control Scheme and

Indirect Field Oriented Control Scheme Using Space Vector Modulation

ABSTRACT:

Induction

motors are the starting point to design an electrical drive system which is

widely used in many industrial applications. In modern control theory,

different mathematical models describe induction motor according to the

employed control methods. Vector control strategy can be applied to this

electrical motor type in symmetrical three phase version or in unsymmetrical

two phase version. The operation of the induction motor can be analyzed similar

to a DC motor through this control method. With the Joint progress of the power

electronics and numerical electronics it is possible today to deal with the

axis control with variable speed in low power applications. With these

technological projections, various command approaches have been developed by

the scientific community to master in real time, the flux and the torque of the

electrical machines, the direct torque control (DTC) scheme being one of the

most recent steps in this direction. This scheme provides excellent properties

of regulation without rotational speed feedback. In this control scheme the

electromagnetic torque and stator flux magnitude are estimated with only stator

voltages and currents and this estimation does not depend on motor parameters

except for the stator resistance. In this dissertation report conventional DTC

scheme has been described. Induction motor has been simulated in stationary d-q

reference frame and its free acceleration characteristics are drawn.

Conventional DTC scheme has been simulated with a 50 HP, 460V, 60 Hz induction

motor. Literature review has been done to study the recent improvements in DTC

scheme which somehow is able to overcome the drawbacks of conventional one. The

space vector modulation technique (SVPWM) is applied to 2 level inverter

control in the vector control based induction motor drive system, thereby

dramatically reducing the torque ripple. Later in this project space vector PWM

technique will be applied to DTC drive system to reduce the torque ripple.

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig.1

Block diagram of conventional DTC scheme for IM drives

EXPECTED SIMULATION RESULTS:

Fig.2

Electromagnetic torque

Fig.3

Rotor speed

Fig.4

Stator current

Fig.5

d-axis stator flux

Fig.6

q-axis stator flux

For

TL = 2 Nm

Fig.7

Electromagnetic torque

Fig.8

Rotor speed

Fig.9

Trajectory of d axis and q axis stator flux in stationary reference frame

Fig.10 Electromagnetic torque

Fig.10 Electromagnetic torque

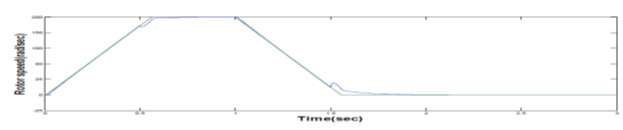

Fig.11

Rotor speed

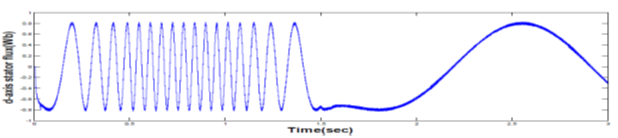

Fig.12

d-axis stator flux

Fig.13

q-axis stator flux

Fig.14

d-axis stator current

Fig.16 Mean value of

Phase voltage of inverter

Fig.17

Line voltage output of inverter

Fig.18

Electromagnetic torque

Fig.19

Rotor speed

Fig.20

q-axis stator flux

Fig.21

d-axis stator flux

CONCLUSION:

For

any IM drives, Direct torque control is one of the best controllers proposed so

far. It allows decoupled control of motor stator flux and electromagnetic

torque. From the analysis it is proved that, this strategy of IM control is

simpler to implement than other vector control methods as it does not require

pulse width modulator and co-ordinate transformations. But it introduces undesired

torque and current ripple. DTC scheme uses stationary d-q reference

frame with d-axis aligned with the stator axis. Stator voltage space

vector defined in this reference frame control the torque and flux. The main

inferences from this work are:

1.

In transient state, by selecting the fastest accelerating voltage vector which

produces maximum slip frequency, highest torque response can be obtained.

2.

In steady state, the torque can be maintained constant with small switching

frequency by the torque hysteresis comparator by selecting the accelerating

vector and the zero voltage vector alternately.

3.

In order to get the optimum efficiency in steady state and the highest torque

response in transient state at the same time, the flux level can be

automatically adjusted.

4.

If the switching frequency is extremely low, the control circuit makes some

drift which can be compensated easily to minimize the machine parameter variation.

The

estimation accuracy of stator flux is very much essential which mostly depends

on stator resistance because an error in stator flux estimation will affect the

behavior of both torque and flux control loops. The torque and current ripple

can be minimized by employing space vector modulation technique.

REFERENCES:

[1]

B. K.Bose. 1997. Power Electronics and Variable Frequency Drives. IEEE Press,

New York.

[2]

Kazmierkowski, R.Krishnan, Blaabjerg, Control in Power Electronics, Selected

Problems.

[3]

Takahashi Isao, Noguc hi Tos hihiko, „‟A New Quick-Response and High-Efficiency

Control Strategy of an Induction Motor‟‟, IEEE Transactions on Industry

Applications, Vol. IA-22 No-5, Sept/Oct 1986.

[4]

Thomas G.Habetler, Francesco Profumo, Michele Pastorelli and Leon M. Tolbert

“Direct Torque Control of IM us ing Space Vector Modulation” IEEE

Transactions on Industry Applications, Vol.28, No.5, Sept/Oct 1992.

[5]

E.Bassi, P. Benzi, S. Buja, “A Field Orientation Scheme for

Current-Fed Induction Motor Drives Based on the Torque Angle Closed-Loop

Control” IEEE Transactions on Industry Applications, Vol. 28, No. 5,

Sept./ Oct. 1992.