Direct torque control of

squirrel cage induction motor for optimum current ripple using three-level

inverter

ABSTRACT:

Three-level

neutral point clamped (NPC) inverters have been widely used in medium voltage

applications. In this study, direct torque control strategy for sensorless

squirrel-cage induction motor (SQIM) using NPC three-level inverter is

presented. The proposed control strategy optimises the current ripple in steady

state and also gives a high dynamic performance of torque in transient state.

The advantage of having low dv/dt for three-level inverter output voltage is

retained. The control strategy is verified on a 7.5 hp SQIM drive with

three-level insulated-gate bipolar transistor (IGBT) inverter. Experimental

results validate the steady state and the dynamic performance of the proposed

control strategy.

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Figure 1: Three-level diode clamped inverter

Figure

2: Block diagram of the controller

EXPECTED SIMULATION RESULTS:

Figure 3: Trajectory of the

stator flux in stationary α –β Plane

Figure

4: Experimentally estimated rotor flux (Ѱrsα, Ѱrsβ) at a

frequency of 5 Hz

Figure

5: Three-level motor line voltage

Figure

6: Torque reference and actual torque ripple

Figure 7: Steady

state speed and line current waveforms (a) Experimental waveform of speed (ωe) and line current (is) at steady state (b)

Zoomed waveform of line current showing the ripples

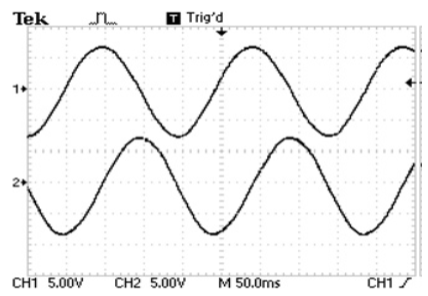

Figure 8:

Experimental waveforms of speed (ωe) and line current (is)

at steady state at 14 Hz

Figure

9: Torque reference (m*d)

and actual torque (md) during transient

CONCLUSION:

This paper has introduced a direct torque and flux control for SQIM

using neutral point clamped three-level inverter. The operation of the drive is

divided into two regions – low frequency operation and high-frequency

operation. Separate switching strategies are proposed for these two regions of operation.

The proposed strategy optimises the switching to have minimum dv/dt in the

motor line voltages. It also optimises the current ripple in steady state and

gives a fast torque response during transient. There is an effective reduction

in the dv/dt applied to the motor terminals. This in turn reduces the bearing

current and shaft voltages [14, 15] of the

motor thereby increasing the life of the motor. Experimental results using SQIM

and three-level inverter validate the proposed strategy.

REFERENCES:

[1]

NABAE A., TAKAHASHI I., AKAGI H.: ‘A new neutral point clamped inverter’, IEEE

Trans. Ind. Appl., 1981, IA-17, (5), pp. 518–523

[2]

LAI J.-S., PENG F.Z.: ‘Multilevel converters – a new breed of power

converters’, IEEE Trans. Ind. Appl., 1996, 32, (3), pp. 509–517

[3]

MCGRATH B.P., HOLMES D.G., LIPO T.A.: ‘Optimized space vector switching

sequences for multilevel inverters’, IEEE Trans. Power Electron., 2003, 18,

(6), pp. 1293–1301

[4]

BUJA G.S., KAZMIERKOWSKI M.P.: ‘Direct torque control of PWM inverter-fed AC

motors – a survey’, IEEE Trans. Power Electron., 2004, 51, (4), pp. 744–757

[5]

CASADEI D., SERRA G., TANI A., ZARRI L.: ‘Assessment of direct torque control

for induction motor drives’, Bull. Pol. Acad. Sci., Techn. Sci., 2006, 54, (3),

pp. 237–254