ABSTRACT

Current control based on hysteresis algorithms are widely

used in different applications, such as motion control, active filtering or

active/reactive power delivery control in distributed generation systems. The

hysteresis current control provides to the system a fast and robust dynamic

response, and requires a simple implementation in standard digital signal platforms.

On the other hand, the main drawback of classical hysteresis current control

lies in the fact that the switching frequency is variable, as the hysteresis band is

fixed. In this paper a variable band hysteresis control algorithm will be

presented. As it will be shown, this variable band permits overcoming the aforementioned

problem giving rise to an almost constant switching frequency. The performance

of this algorithm, together with classical hysteresis controls and proportional

resonant (PR) controllers, has been evaluated in three different single-phase

PV inverter topologies, by means of simulations performed with PSIM. In

addition, the behavior of the thermal losses when using each control structure

in such converters has been studied as well.

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig. 1. Basic Current Control

Scheme in a single phase inverter.

EXPECTED

SIMULATION RESULTS:

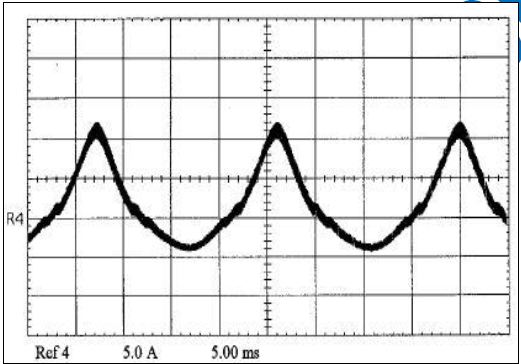

Fig.

2. Behavior of the current and the voltage at the output of the converter

when

using the H5 topology.

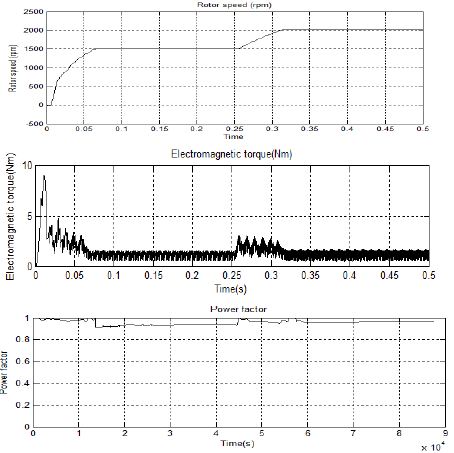

Fig.

3. Behavior of the current and the voltage at the output of the converter

when

using the HERIC topology.

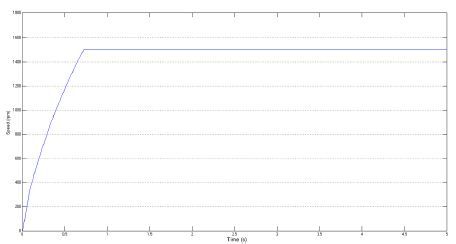

Fig.

4. Behavior of the current and the voltage at the output of the converter

when

using the or HB-ZVR topology.

CONCLUSION

A

hysteresis current control algorithm based on an adaptive hysteresis band for

single phase PV converter topologies has been presented in this paper. As it

has been shown analytically and by means of simulations this algorithm permits

obtaining a fixed switching frequency in all the tested topologies. The main

drawback of the conventional fixed hysteresis band current control is that

generates excessive current ripple because modulation frequency varies within a

band. This modulation

frequency variation makes complicated the output filter design. Adaptive

hysteresis band current control keeps the good performance of the fixed band

hysteresis current control and additionally permits an easier output filter

design due that the switching frequency is almost constant. On the other hand,

switching losses can be reduced by using this adaptive hysteresis band current control.

The analyzed topologies are the more widely used in transformerless

single-phase PV systems (H5 and HERIC). Based in the previously comparative

simulations results it can be concluded that in the case of H5 topology losses

are concentrated in S5. In case of HERIC topology losses are located among S1,

S2, S3 and S4. Finally in HB-ZVR single phase topology, losses are located in

S5. These results mean that in each case, the losses distribution is not the

same and a different thermal design should be done.

REFERENCES

[1] L.

Malesani, P. Mattavelli, P. Tomasin, “High Performance Hysteresis Modulation

Technique for Active Filters”, IEEE Transactions on Power Electronics,

Volume 12, September 1997.

[2] J.

Holtz and S. Stadtfeld, “A Predictive Controller for the Stator Current Vector

of AC Machine-fed from a Switched Voltage Source”, in Proc. Int. Power

Electronics Conference Rec. (Tokyo), 1983, pp. 1665-1675.

[3] M.

Ciobotaru, R. Teodorescu, and F. Blaabjerg, “Control of Single-Stage Single-Phase

PV Inverter”, European Conference on Power Electonics and

Applications, 2005.

[4] Y.

Hayashi, N. Sato, K. Takahashi, “A Novel Control of a Current- Source Active

Filter for ac Power System Harmonic Compensation”, IEEE Transactions on

Industrial Applications, Vol. 27, No. 2, March/April 1991.

[5] T.

Kato, K. Miyao, “Modified Hysteresis Control with Minor Loops for Single-Phase

Full-Bridge Inverters”, Doshisha University, Kyoto Japan, 88CH2565-0/88/0000-0689$01.00,

1988 IEEE.