asokatechnologies@gmail.com 09347143789/09949240245

Search This Blog

Wednesday, 4 February 2015

Wednesday, 21 January 2015

Study of Induction Motor Drive with Direct Torque Control Scheme and Indirect Field Oriented Control Scheme Using Space Vector Modulation

Study of Induction Motor Drive with Direct Torque Control Scheme and

Indirect Field Oriented Control Scheme Using Space Vector Modulation

ABSTRACT:

Induction

motors are the starting point to design an electrical drive system which is

widely used in many industrial applications. In modern control theory,

different mathematical models describe induction motor according to the

employed control methods. Vector control strategy can be applied to this

electrical motor type in symmetrical three phase version or in unsymmetrical

two phase version. The operation of the induction motor can be analyzed similar

to a DC motor through this control method. With the Joint progress of the power

electronics and numerical electronics it is possible today to deal with the

axis control with variable speed in low power applications. With these

technological projections, various command approaches have been developed by

the scientific community to master in real time, the flux and the torque of the

electrical machines, the direct torque control (DTC) scheme being one of the

most recent steps in this direction. This scheme provides excellent properties

of regulation without rotational speed feedback. In this control scheme the

electromagnetic torque and stator flux magnitude are estimated with only stator

voltages and currents and this estimation does not depend on motor parameters

except for the stator resistance. In this dissertation report conventional DTC

scheme has been described. Induction motor has been simulated in stationary d-q

reference frame and its free acceleration characteristics are drawn.

Conventional DTC scheme has been simulated with a 50 HP, 460V, 60 Hz induction

motor. Literature review has been done to study the recent improvements in DTC

scheme which somehow is able to overcome the drawbacks of conventional one. The

space vector modulation technique (SVPWM) is applied to 2 level inverter

control in the vector control based induction motor drive system, thereby

dramatically reducing the torque ripple. Later in this project space vector PWM

technique will be applied to DTC drive system to reduce the torque ripple.

SOFTWARE: MATLAB/SIMULINK

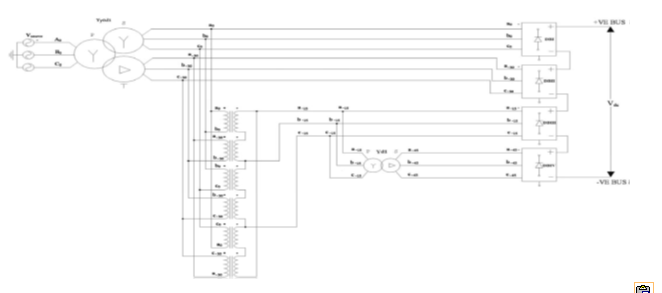

BLOCK DIAGRAM:

Fig.1

Block diagram of conventional DTC scheme for IM drives

EXPECTED SIMULATION RESULTS:

Fig.2

Electromagnetic torque

Fig.3

Rotor speed

Fig.4

Stator current

Fig.5

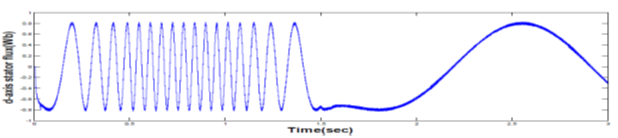

d-axis stator flux

Fig.6

q-axis stator flux

For

TL = 2 Nm

Fig.7

Electromagnetic torque

Fig.8

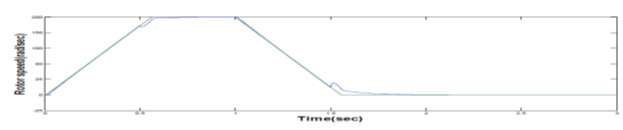

Rotor speed

Fig.9

Trajectory of d axis and q axis stator flux in stationary reference frame

Fig.10 Electromagnetic torque

Fig.10 Electromagnetic torque

Fig.11

Rotor speed

Fig.12

d-axis stator flux

Fig.13

q-axis stator flux

Fig.14

d-axis stator current

Fig.16 Mean value of

Phase voltage of inverter

Fig.17

Line voltage output of inverter

Fig.18

Electromagnetic torque

Fig.19

Rotor speed

Fig.20

q-axis stator flux

Fig.21

d-axis stator flux

CONCLUSION:

For

any IM drives, Direct torque control is one of the best controllers proposed so

far. It allows decoupled control of motor stator flux and electromagnetic

torque. From the analysis it is proved that, this strategy of IM control is

simpler to implement than other vector control methods as it does not require

pulse width modulator and co-ordinate transformations. But it introduces undesired

torque and current ripple. DTC scheme uses stationary d-q reference

frame with d-axis aligned with the stator axis. Stator voltage space

vector defined in this reference frame control the torque and flux. The main

inferences from this work are:

1.

In transient state, by selecting the fastest accelerating voltage vector which

produces maximum slip frequency, highest torque response can be obtained.

2.

In steady state, the torque can be maintained constant with small switching

frequency by the torque hysteresis comparator by selecting the accelerating

vector and the zero voltage vector alternately.

3.

In order to get the optimum efficiency in steady state and the highest torque

response in transient state at the same time, the flux level can be

automatically adjusted.

4.

If the switching frequency is extremely low, the control circuit makes some

drift which can be compensated easily to minimize the machine parameter variation.

The

estimation accuracy of stator flux is very much essential which mostly depends

on stator resistance because an error in stator flux estimation will affect the

behavior of both torque and flux control loops. The torque and current ripple

can be minimized by employing space vector modulation technique.

REFERENCES:

[1]

B. K.Bose. 1997. Power Electronics and Variable Frequency Drives. IEEE Press,

New York.

[2]

Kazmierkowski, R.Krishnan, Blaabjerg, Control in Power Electronics, Selected

Problems.

[3]

Takahashi Isao, Noguc hi Tos hihiko, „‟A New Quick-Response and High-Efficiency

Control Strategy of an Induction Motor‟‟, IEEE Transactions on Industry

Applications, Vol. IA-22 No-5, Sept/Oct 1986.

[4]

Thomas G.Habetler, Francesco Profumo, Michele Pastorelli and Leon M. Tolbert

“Direct Torque Control of IM us ing Space Vector Modulation” IEEE

Transactions on Industry Applications, Vol.28, No.5, Sept/Oct 1992.

[5]

E.Bassi, P. Benzi, S. Buja, “A Field Orientation Scheme for

Current-Fed Induction Motor Drives Based on the Torque Angle Closed-Loop

Control” IEEE Transactions on Industry Applications, Vol. 28, No. 5,

Sept./ Oct. 1992.

Sunday, 18 January 2015

24-Pulse Rectifier Realization By 3-Phase To Four 3-Phase Transformation Using Conventional Transformers

24-Pulse Rectifier Realization By 3-Phase To Four 3-Phase

Transformation Using Conventional Transformers

ABSTRACT:

A 24-pulse rectifier has been designed for high

voltage, low current applications. Four 3-phase systems are obtained from a

single 3-phase source using novel interconnection of conventional single- and 3-phase

transformers. From two 30º displaced 3-phase systems feeding two 6-pulse

rectifiers that are series connected, a 12-pulse rectifier topology is

obtained. Thus, from the four 3-phase systems that are displaced by 15º two

12-pulse rectifiers are obtained that are cascaded to realize a 24-pulse

rectifier. Phase shifts of 15º and 30º are made using phasor addition of

relevant line voltages with a combination of single-phase and three-phase

transformers respectively. PSCAD based simulation and experimental results that

confirm the design efficacy are presented.

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Figure 1 24-pulse rectifier realized by transforming

a single 3-phase system to four 3-phase systems using conventional single- and

three-phase transformers

EXPECTED SIMULATION RESULTS:

Figure 2 Input line voltages Va0b0, Vb0c0 and Vc0a0 at

diode bridge I

Figure 3 Input line voltages Va30b30, Vb30c30 and Vc30a30

at diode bridge II

Figure 4 Input line voltages Va15b15, Vb15c15 and Vc15a15

at diode bridge III

Figure 5 Input line voltages Va45b45, Vb45c45 and Vc45a45

at diode bridge IV

Figure 6 Line current in phase a of y0 winding of

Yy0d1 main transformer

Figure 7 Line current in phase a of d1 winding of

Yy0d1 main transformer

Figure 8 Six-pulse dc output voltage of diode bridge,

DBI

Figure 9 DC 6-pulse output voltage of diode bridge,

DBII

Figure 10 DC 12-pulse output voltage by cascading

diode bridges I and II

Figure 11 Six-pulse dc output voltage of diode

bridge, DBIII

Figure 12 DC 6-pulse output voltage of diode bridge,

DBIV

Figure 13 DC 12-pulse output voltage by cascading

diode bridges III and IV

Figure 14 DC 24-pulse voltage by cascading DBI,

DBII, DBIII and DBIV

Figure 15 Line current in phase a of Y winding of

Yy0d1 main transformer

Figure 16 Line current in phase a of Y winding of

Yy0d1 main transformer

Figure 17 Panned view of 24-pulse dc voltage

Figure 18 24-pulse dc voltage

Figure 19 Experimental set up

CONCLUSION:

A

24-pulse rectifier is realized by conventional transformers that meets the

theoretical harmonic

and

ripple estimates.

REFERENCES:

[1] IEEE Recommended Practices and

Requirements for Harmonics Control in Electric Power Systems, IEEE Std. 519, 1992.

[2]

Electromagnetic Compatibility (EMC)—Part 3: Limits-Section 2: Limits for

Harmonic Current Emissions (Equipment Input Current (16A per Phase),

IEC1000-3-2, Dec., 1995.

[3]

Draft-Revision of Publication IEC 555-2: Harmonics, Equipment for Connection to

the Public Low Voltage Supply System, IEC SC 77A, 1990.

[4]

Bhim Singh, B. N. Singh, A. Chandra, Kamal Al-Haddad, Ashish Pandey, and D. P.

Kothari, “A Review of Three-Phase Improved Power Quality AC-DC Converters”,

IEEE Trans. Ind. Electron., vol. 51, No. 3, June 2004, 641-660.

[5]

S. Choi, “New pulse multiplication technique based on six pulse thyristor

converters for high power applications,” IEEE Trans. Ind. Appl., vol.

38, no. 1, pp. 131–136, Jan./Feb. 2002.

Sunday, 4 January 2015

Implementation Of Perturb And Observe MPPT Of PV System with Direct Control Method Using Buck And Buck boost Converters

Implementation Of Perturb And Observe MPPT Of PV System with Direct Control

Method Using Buck And Buck boost Converters

ABSTRACT:

The Maximum Power Point Tracking (MPPT) is a

technique used in power electronic circuits to extract maximum energy from the

Photovoltaic (PV) Systems. In the recent decades, photovoltaic power generation

has become more important due its many benefits such as needs a few maintenance

and environmental advantages and fuel free. However, there are two major

barriers for the use of PV systems, low energy conversion efficiency and high

initial cost. To improve the energy efficiency, it is important to work PV system

always at its maximum power point. So far, many researches are conducted and

many papers were published and suggested different methods for extracting

maximum power point. This paper presents in details implementation of Perturb

and Observe MPPT using buck and buck-boost Converters. Some results such as

current, voltage and output power for each various combination have been

recorded. The simulation has been accomplished in software of MATLAB Math works.

KEYWORDS

1. Maximum Power Point Tracking

2. Perturb and

Observe

3. DC-DC Converters

4. Photovoltaic System

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Figure

1. PV module and dc/ dc converter with MPPT

Figure

2. Block diagram of a PV array connected to the load

EXPECTED SIMULATION RESULTS:

Figure

3. Output current, voltage and power of PV panel (insolation changed from 400

to 200 w/ m² at a time of 4.915 sec.)

Figure

4. Output current, voltage and power of buck converter with P&O algorithm

(Insolation

changed from 400 to 200 w/ m² at a time of 4.915 sec.)

Figure

5. output current, voltage and power of PV panel (Insolation changed from 400

to 200 w/ m² at a time of 5.017 sec.)

Figure

6. Output current, voltage and power of buck-boost converter with P&O

algorithm

(Insolation

changed from 400 to 200 w/ m² at a time of 5.017 sec.)

CONCLUSION:

P&O

MPPT method is implemented with MATLAB-SIMULINK for simulation. The MPPT method

simulated in this paper is able to improve the dynamic and steady state

performance of the PV system simultaneously. Through simulation it is observed

that the system completes the maximum power point tracking successfully despite

of fluctuations. When the external environment changes suddenly the system can

track the maximum power point quickly. Both buck and buck-boost converters have

succeeded to track the MPP but, buck converter is much more effective specially

in suppressing the oscillations produced due the use of P&O technique.

REFERENCES:

[1]

A.P.Yadav, S. Thirumaliah and G. Harith. “Comparison of MPPT Algorithms for

DC-DC Converters Based PV Systems” International Journal of Advanced Research

in Electrical, Electronics and Instrumentation Engineering Vol. 1, Issue 1,

July 2012.

[2]

Y.-H.Chang and C.-Y. Chang, "A Maximum Power Point Tracking of PV System

by Scaling Fuzzy Control," presented at International Multi Conference of

Engineers and Computer Scientists, Hong Kong, 2010.

[3]

S.Mekhilef, "Performance of grid connected inverter with maximum power

point tracker and power factor control," International Journal of Power

Electronics, vol.1, pp. 49-62.

[4]

M.E.Ahmad and S.Mekhilef, "Design and Implementation of a Multi Level

Three-Phase Inverter with Less Switches and Low Output Voltage

Distortion," Journal of Power Electronics, vol. 9, pp. 594- 604, 2009.

[5]

H.N.Zainudin and S. Mekhilef, "Comparison Study of Maximum Power Point

Tracker Techniques for PV Systems" Proceedings of the 14th International Middle

East Power Systems Conference (MEPCON’10), Cairo University, Egypt, December

19-21, 2010.

Simulation and Analysis of Perturb and Observe MPPT Algorithm for PV Array Using ĊUK Converter

Simulation and Analysis of Perturb and Observe MPPT

Algorithm for PV Array Using ĊUK Converter

ABSTRACT:

This

paper presents the comparative analysis between constant duty cycle and Perturb

& Observe (P&O) algorithm for extracting the power from Photovoltaic

Array (PVA). Because of nonlinear characteristics of PV cell, the maximum power

can be extract under particular voltage condition. Therefore, Maximum Power

Point Tracking (MPPT) algorithms are used in PVA to maximize the output power.

In this paper the

MPPT algorithm is implemented using Ćuk converter. The

dynamics of PVA is simulated at different solar irradiance and cell temperature.

The P&O MPPT technique is a direct control method enables ease to implement

and less complexity.

KEYWORDS

1. Photovoltaic Array (PVA)

2. MPPT

3. ĆUK Converter

SOFTWARE: MATLAB/SIMULINK

BLOCK DIAGRAM:

Fig. 1: Block Diagram of MPPT

Using PI Controller

Fig. 2: Block Diagram of Direct

Duty Cycle (δ) Control MPPT

EXPECTED SIMULATION RESULTS:

Fig. 3: MATLAB/SIMULINK Model of PVCC for δ

=0.6

Fig. 4: Output Power Curve of the PV Module and Ćuk Converter for Constant

δ = 0.6 and Different β.

Fig. 5: Output Power Curve of the PV Module and Ćuk Converter for Constant

δ = 0.6 and Different T

Fig. 6: MATLAB/SIMULINK Model

of PVCC Using P & O Algorithm

Fig. 7: Output Power Curve of the PV Module and Ćuk

Converter for Different β and P&O MPPT

Fig. 8: Output Power Curve of the PV Module

and Ćuk Converter for Different T and P & O MPPT.

CONCLUSION:

In

this paper, P&O and constant duty cycle algorithm of MPPT is implemented

using ĆUK converter. The model is

simulated with MATLAB/SIMULINK. It is shown that PV system

output power increases with rise in solar irradiance and fall in cell temperature.

Therefore, solar cell performance better in winter season than summer. The

P&O gives the optimum duty cycle as compare to Constant duty cycle control,

to extract the maximum power from PV system.

REFERENCES:

[1]

Ali Chermitti, Omar Boukli-Hacene and Samir Mouhadjer (2012) “Design of a

Library of Components for Autonomous Photovoltaic System under Matlab/Simulink”,

International Journal of Computer Applications (0975 – 8887), Volume

53– No.14.

[2]

Ankur Bhattacharjee (2012) “Design and Comparative Study of Three Photovoltaic

Battery Charge Control Algorithms in MATLAB/SIMULINK Environment”, International

Journal of Advanced Computer Research (ISSN (print): 2249-7277 ISSN

(online): 2277-7970), Volume-2 Number-3 Issue-5.

[3]

Athimulam Kalirasu and Subharensu Sekar Dash (2010) “Simulation of Closed

Loop Controlled Boost Converter for Solar Installation,” SERBIAN JOURNAL

OF ELECTRICAL ENGINEERING, Vol. 7, No. 1.

[4]

Azadeh Safari and Saad Mekhilef (2011) “Simulation and Hardware Implementation

of Incremental Conductance MPPT with Direct Control Method Using Cuk

Converter”, IEEE Transaction on Industrial Electronics, Vol.58,

no.4.

[5]

E. Durán, M.B. Ferrera, J.M. Andújar, M.S. Mesa (2011) “I-V and P-V Curves

Measuring System for PV Modules based on DC-DC Converters and Portable

Graphical Environment” IEEE, 978-1-4244.

Subscribe to:

Comments (Atom)