ABSTRACT:

A novel bidirectional dc–dc

converter is presented in this paper. The circuit configuration of the proposed

converter is very simple. The proposed converter employs a coupled inductor with

same winding turns in the primary and secondary sides. In step-up mode, the

primary and secondary windings of the coupled inductor are operated in parallel

charge and series discharge to achieve high step-up voltage gain. In step-down mode,

the primary and secondary windings of the coupled inductor are operated in series

charge and parallel discharge to achieve high step-down voltage gain. Thus, the

proposed converter has higher step-up and step-down voltage gains than the

conventional bidirectional dc–dc boost/buck converter. Under same electric

specifications for the proposed converter and the conventional bidirectional

boost/buck converter, the average value of the switch current in the proposed converter

is less than the conventional bidirectional boost/buck converter. The operating

principle and steady-state analysis are discussed in detail. Finally, a 14/42-V

prototype circuit is implemented to verify the performance for the automobile

dual-battery system.

KEYWORDS:

1. Bidirectional dc–dc

converter

2. Coupled inductor

SOFTWARE: MATLAB/SIMULINK

Fig. 1. Proposed bidirectional dc–dc

converter.

Fig.

2. Some experimental waveforms of the proposed converter in step-up

mode.

(a) iL1, iL2, and iL,

(b) iS1, iS2, and iS3.

(c) vDS1, vDS2, and vDS3.

Fig.

3. Dynamic response of the proposed converter in step-up mode for the

output

power variation between 20 and 200 W.

Fig.

4. Some experimental waveforms of the proposed converter in step down

mode.

(a) iLL, iL1, and iL2,

(b) iS3, iS1, and iS2.

(c) vDS3, vDS1, and vDS2.

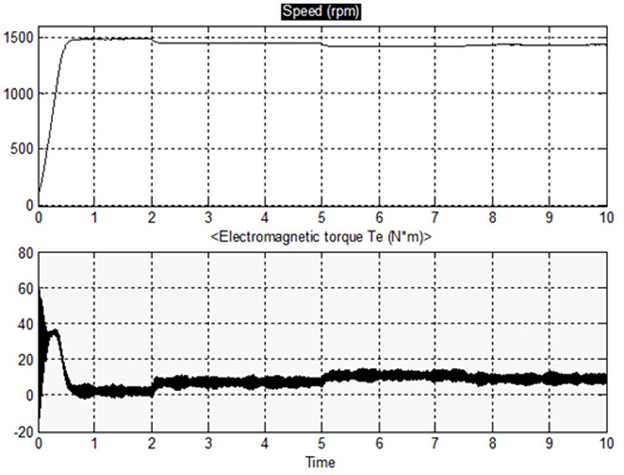

Fig.

5. Dynamic response of the proposed converter in step-down mode for

the

output power variation between 20 and 200 W.

CONCLUSION:

This

paper researches a novel bidirectional dc–dc converter. The circuit

configuration of the proposed converter is very simple. The proposed converter

has higher step-up and step-down voltage gains and lower average value of the

switch current than the conventional bidirectional boost/buck converter. From

the experimental results, it is see that the experimental waveforms agree with

the operating principle and steady-state analysis. At full-load condition, the

measured efficiency is 92.7% in stepup mode and is 93.7% in step-down mode.

Also, the measured efficiency is around 92.7%–96.2% in step-up mode and is around

93.7%–96.7% in step-down mode, which are higher than the conventional

bidirectional boost/buck converter.

REFERENCES:

[1]

M. B. Camara, H. Gualous, F. Gustin, A. Berthon, and B. Dakyo, “DC/DC converter

design for supercapacitor and battery power management in hybrid vehicle

applications—Polynomial control strategy,” IEEE Trans. Ind. Electron.,

vol. 57, no. 2, pp. 587–597, Feb. 2010.

[2]

T. Bhattacharya, V. S. Giri, K. Mathew, and L. Umanand, “Multiphase bidirectional

flyback converter topology for hybrid electric vehicles,” IEEE Trans. Ind.

Electron., vol. 56, no. 1, pp. 78–84, Jan. 2009.

[3]

Z. Amjadi and S. S. Williamson, “A novel control technique for a switched-capacitor-converter-based

hybrid electric vehicle energy storage system,” IEEE Trans. Ind. Electron.,

vol. 57, no. 3, pp. 926–934, Mar. 2010.

[4]

F. Z. Peng, F. Zhang, and Z. Qian, “A magnetic-less dc–dc converter for dual-voltage

automotive systems,” IEEE Trans. Ind. Appl., vol. 39, no. 2, pp. 511–518,

Mar./Apr. 2003.

[5]

A. Nasiri, Z. Nie, S. B. Bekiarov, and A. Emadi, “An on-line UPS system with

power factor correction and electric isolation using BIFRED converter,” IEEE

Trans. Ind. Electron., vol. 55, no. 2, pp. 722–730, Feb. 2008.