ABSTRACT:

Now-a-days, sensorless speed control modes of operation are

becoming standard solutions in the area of electric drives. The technological

developments require a compact and efficient drive to meet the challenging

strategies in operation of the system. This paper provides a speed sensorless

control of an Induction motor with a model based adaptive controller with

stator current vectors. The purpose of the proposed control scheme is to create

an algorithm that will make it possible to control induction motors without

sensors. A closed loop estimation of the system with robustness against parameter

variation is used for the control approach. A Model Reference Adaptive System

(MRAS) is one of the major approaches used for adaptive control. The MRAS

provides relatively easy implementation with a higher speed adaptation algorithm.

MRAS proposed in this paper owing to its low complexity and less computational

effort proposes a feasible methodology to control the speed of an Induction

Motor (1M) drive without using speed sensors. Simulations results validate the

effectiveness of this technique.

KEYWORDS:

1.

Indirect Field oriented

control

2.

Induction motor drive

3.

Sensorless speed

estimation

4.

Model Reference Adaptive control.

SOFTWARE: MATLAB/SIMULINK

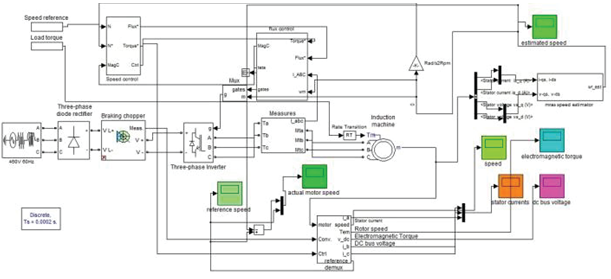

BLOCK DIAGRAM:

Fig.1.

Proposed Block Diagram of MRAS based 1M drive using

PI controller.

Fig.2.

Overall Simulink model of sensorless control of

induction motor using MRAS with PI controller.

EXPECTED SIMULATION RESULTS:

CONCLUSION:

The model based control scheme is basically an adaptive control

mechanism. The reference model of the proposed system consists of the response

to be obtained for the input conditions. The adaptive mechanism continuously monitors

the adaptable parameter (speed in this case). The

adaptable parameter is continuously subjected to changes based

on its deviation obtained by comparing it with the response of the reference

model. The speed estimation algorithm in MRAS is computationally less

intensive. MRAS is a relatively simple algorithm and hence less sophisticated

processing can be employed. MRAS strategy is more robust than the conventional

one. This makes it better suited if the drive is to be operated in hostile environments.

Owing to less sophisticated processing requirements, MRAS technique costs

cheaper and hence overall cost of the drive is reduced. With lower cost and greater

reliability without mounting problems, the sensorless vector control schemes

have made remarkable developments in electric drive technology. Due to lesser rise

time taken by MRAS, this method gives faster steady state response and this

scheme has better reliability than the conventional scheme.

REFERENCES:

[I] Teresa Orlowska - Kowalska and Mateusz Dybkowski ,

"Stator Current based MRAS estimator for a wide range speed Sensor less induction

motor drives", IEEE Transactions on Industrial Electronics vo1.51, No. 4,

April 2010, pp. 1296 - 1308.

[2] B. K. Bose, Power Electronics and Motor Drives, Pearson Education

Inc., Delhi, India, 2003.

[3] M. Rodic and K. Jezernik, "Speed-sensorless

sliding-mode torque control of induction motor," IEEE Transactions on

Industrial Electronics, vol. 49, no. I, pp. 87-95, February 2002.

[4] L. Harnefors, M. Jansson, R. Ottersten and K. Pietilainen, "Unified

sensorless vector control of synchronous and induction motors," IEEE

Transactions on Industrial Electronics, vol. 50, no.

1, pp. 153-160, February 2003.

[5] M. Comanescu and L. Xu, "An improved flux observer

based on PLL frequency estimator for sensorless vector control of induction motors,"

IEEE Transactions on Industrial Electronics, vol. 53, no. 1, pp. 50-56,

February 2006.