Brushless dc (BLDC) motors are very popular and are

replacing brush motors in numerous applications due to its superior electrical

and mechanical characteristics owing to its trouble free construction. This

paper presents the BLDC motor sensorless speed control system with fuzzy logic

implementation. The sensorless techniques based on the back EMF sensing and the

rotor position detection with a high starting torque is suggested. The rotor

position is aligned at standstill for without an additional sensor. Also, the

stator current can be easily adjusted by modulating the pulse width of the

switching devices during alignment which will be helpful to reduce cost and

complexity of the drive system without compromising the performance. The design

analysis and simulation of the proposed system is done using MATLAB version

2010a and the simulation results of sensored drive using PI controller and

sensorless drive using proposed methods are analyzed.

KEYWORDS:

1.

Brushless dc motor

2.

Hall sensored

drive

3.

PI controller

4.

Back EMF sensorless drive

5.

Fuzzy controller

SOFTWARE: MATLAB/SIMULINK

BLOCK

DIAGRAM:

Fig. 1.Proposed block diagram of

sensorless speed control of BLDC motor.

EXPECTED SIMULATION RESULTS:

Fig. 2(a) Variation of

Back EMF signal with reference set at 1400 rpm

Fig. 2(b) Variation of

stator current with reference set at 1400 rpm.

Fig. 3.Generated pulse from fuzzy

logic controller.

Fig. 4(a) Speed

response of sensored drive technique using PI controller.

Fig. 4(b) Speed

response of sensorless drive technique using PI controller.

Fig. 4(c) Speed

response of sensorless drive technique using fuzzy logic controller.

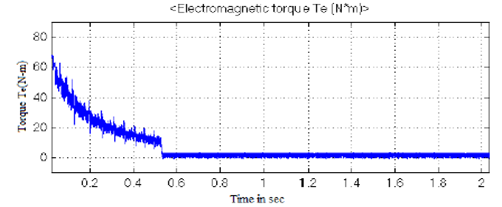

Fig. 5(a) Variation of

Electromagnetic torque with reference set at 1400 rpm under sensorless drive

using PI controller.

Fig. 5(b) Variation of

Electromagnetic torque with reference set at 1400rpm under sensorless drive

using fuzzy logic controller.

CONCLUSION

Sensorless speed control of BLDC motor

drive with fuzzy logic implementation based on comparator with zero crossing

detection have been experimented using MATLAB and evaluation of results are

observed. The simulation results have shown that speed response of the BLDC

motor can be controlled without sensors and also reduces the torque ripple. The

results obtained from sensorless speed control of BLDC motor demonstrates that

the system is less cost compared to sensored control and also good dynamic

performance is obtained. This makes the motor suitable in application such as

fuel pump, robotics and industrial automation. The proposed speed control

scheme is robust, efficient and easy to implement in place of sensored

applications.

REFERENCES

.

[1]

Nobuyuki Matsui, “Sensorless PM Brushless DC

Motor Drives”, IEEE Trans. on

Industrial Electronics, Vol.43, No.2,pp.300-308, April 1996.

[2]

Champa.P,

Somasiri.P, Wipauramonton.P and Nakmahachalasint.P, “Initial Rotor Position

Estimation for Sensorless Brushless DC Drives”, IEEE Trans. on Ind. Applications, Vol.45,No.4, pp.1318-1324,July

2009.

[3]

Somanatham.R, Prasad.P.V.N, Rajkumar.A.D,

“Modelling and Simulation of Sensorless Control of PMBLDC Motor Using

Zero-Crossing Back EMF Detection” IEEE

SPEEDAM 2006 International Symposium on Power Electronics, Drives, Automotive

and Motion.

[4]

Bimal K Bose, “Modern Power Electronics and AC

Drives”, Pearson Education Asia 2002.

[5]

Miller.

T.J.E., “Brushless permanent magnet and reluctance motor drives ", Clarendon Press, Oxford, 1989.